-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 15, 2025 09:54

Back to list

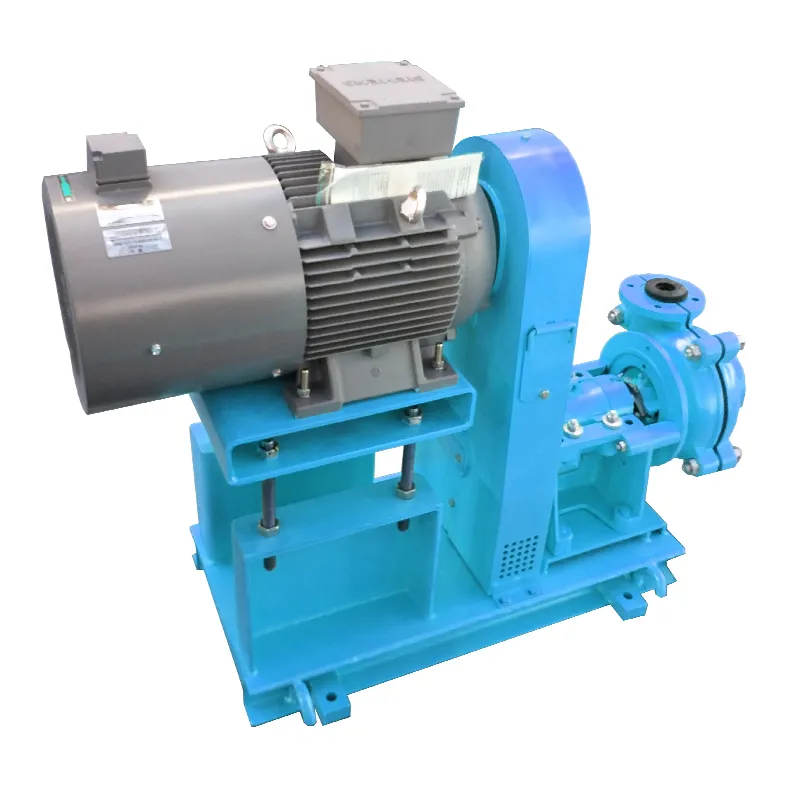

china slurry pump selection

Choosing the right slurry pump for your applications can dramatically impact the efficiency and longevity of your operations, particularly within industries like mining, chemical processing, and wastewater management. Slurry pumps, known for transporting abrasive and corrosive admixtures, are essential in handling challenging materials that can easily wear down standard pump types. Here’s an authoritative guide to navigating slurry pump selection, steeped in both industry expertise and practical experience.

Operational Efficiency and Power Considerations Energy efficiency is a prime concern when selecting a slurry pump. The power requirements for slurry pumps can be substantial due to the density and abrasiveness of the materials being transported. Efficient pump design can reduce operating costs by lowering the energy consumption. Variable frequency drives (VFDs) and advanced control systems help in matching pump capacity to the specific demand, optimizing operational costs. Review the power setup and compatibility with your existing system configurations to ensure maximum pump performance without excessive energy expenditure. Application-Specific Requirements Every industry or project has unique demands when it comes to slurry pumping. Tailored slurry pump solutions in China address these diverse needs by offering customization options. It’s important to assess the specific gravity, head, flow rate, and pressure conditions under which the pump will operate. For instance, high-lift mining operations may require pumps that deliver high head and flow rates, whereas waste management systems may need pumps that handle varying slurry textures. Customizing pump features to align with these parameters ensures that operational efficiency and durability are prioritized. Supplier Credibility When sourcing slurry pumps, the supplier's reputation and reliability are paramount. Established Chinese manufacturers are known for their innovation, technological expertise, and rigorous quality standards. Ensuring that the pump suppliers have comprehensive quality assurance measures in place, such as ISO certification, provides an added layer of trust. Consider suppliers with a solid track record of customer support and after-sales service, which is crucial in minimizing downtime and maintaining pump performance. With these insights into slurry pump selection, you are equipped to make informed decisions that bottleneck operational efficiencies and extend the life of pumping equipment. By aligning with trusted manufacturers and understanding the intrinsic characteristics of the slurry, you can harness the full potential of slurry pumps for any demanding application.

Operational Efficiency and Power Considerations Energy efficiency is a prime concern when selecting a slurry pump. The power requirements for slurry pumps can be substantial due to the density and abrasiveness of the materials being transported. Efficient pump design can reduce operating costs by lowering the energy consumption. Variable frequency drives (VFDs) and advanced control systems help in matching pump capacity to the specific demand, optimizing operational costs. Review the power setup and compatibility with your existing system configurations to ensure maximum pump performance without excessive energy expenditure. Application-Specific Requirements Every industry or project has unique demands when it comes to slurry pumping. Tailored slurry pump solutions in China address these diverse needs by offering customization options. It’s important to assess the specific gravity, head, flow rate, and pressure conditions under which the pump will operate. For instance, high-lift mining operations may require pumps that deliver high head and flow rates, whereas waste management systems may need pumps that handle varying slurry textures. Customizing pump features to align with these parameters ensures that operational efficiency and durability are prioritized. Supplier Credibility When sourcing slurry pumps, the supplier's reputation and reliability are paramount. Established Chinese manufacturers are known for their innovation, technological expertise, and rigorous quality standards. Ensuring that the pump suppliers have comprehensive quality assurance measures in place, such as ISO certification, provides an added layer of trust. Consider suppliers with a solid track record of customer support and after-sales service, which is crucial in minimizing downtime and maintaining pump performance. With these insights into slurry pump selection, you are equipped to make informed decisions that bottleneck operational efficiencies and extend the life of pumping equipment. By aligning with trusted manufacturers and understanding the intrinsic characteristics of the slurry, you can harness the full potential of slurry pumps for any demanding application.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024