-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 17, 2025 13:10

Back to list

Pump Wear Parts E4083 Rubber Front Guard

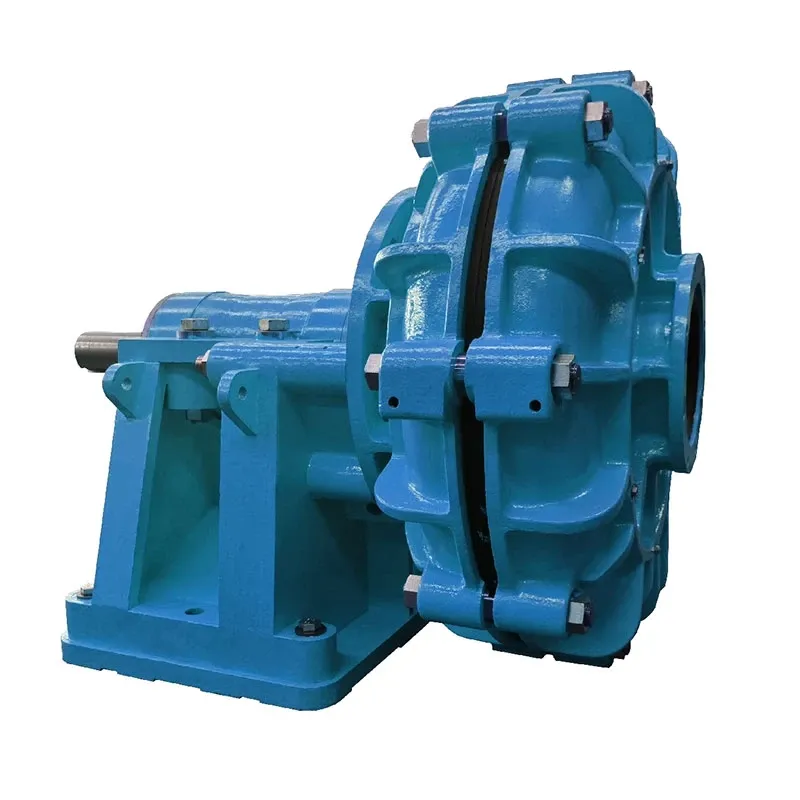

The metal lined slurry pump has proven to be an essential component in various industries, including mining, metallurgy, and construction, thanks to its robust capabilities in handling abrasive and corrosive slurry mixtures. As someone who has spent years examining and optimizing the performance of these pumps, it's clear that their design and construction set them apart from their counterparts.

When considering the investment in a slurry pump, it's vital to count on authoritative sources that emphasize quality and engineering precision. Manufacturers with a long-standing history and expertise in pump design have the credentials necessary to produce components that meet rigorous industry standards and exceed expectations. Longevity, efficiency, and performance are not mere marketing slogans; they are essential product features grounded in research and development. Trust in a metal lined slurry pump is not only derived from its structural merits but also from the knowledgeable producers behind them. An ideal supplier is one who not only delivers a product but also supports it with a comprehensive understanding of customer needs and operational environments. This includes providing accurate performance data, ensuring clear communication regarding maintenance needs, and offering service support to resolve any issues promptly. In evaluating the options available, it’s critical to engage with real, authentic user experiences. Industry forums, case studies, and professional reviews offer valuable insights, enabling potential buyers to make informed decisions. Identifying a pattern of positive user feedback—a clear sign of product trustworthiness—is a strategic step that aligns with the principles of informed purchasing. In conclusion, the metal lined slurry pump stands as a formidable option for industries needing a reliable, long-lasting solution to slurry transportation challenges. Its design is grounded in expertly chosen materials and mechanics that ensure superior performance even in the most demanding environments. Engaging with trusted manufacturers and leveraging real-world customer feedback are key strategies that underpin confidence in choosing the right slurry pump to support industrial operations.

When considering the investment in a slurry pump, it's vital to count on authoritative sources that emphasize quality and engineering precision. Manufacturers with a long-standing history and expertise in pump design have the credentials necessary to produce components that meet rigorous industry standards and exceed expectations. Longevity, efficiency, and performance are not mere marketing slogans; they are essential product features grounded in research and development. Trust in a metal lined slurry pump is not only derived from its structural merits but also from the knowledgeable producers behind them. An ideal supplier is one who not only delivers a product but also supports it with a comprehensive understanding of customer needs and operational environments. This includes providing accurate performance data, ensuring clear communication regarding maintenance needs, and offering service support to resolve any issues promptly. In evaluating the options available, it’s critical to engage with real, authentic user experiences. Industry forums, case studies, and professional reviews offer valuable insights, enabling potential buyers to make informed decisions. Identifying a pattern of positive user feedback—a clear sign of product trustworthiness—is a strategic step that aligns with the principles of informed purchasing. In conclusion, the metal lined slurry pump stands as a formidable option for industries needing a reliable, long-lasting solution to slurry transportation challenges. Its design is grounded in expertly chosen materials and mechanics that ensure superior performance even in the most demanding environments. Engaging with trusted manufacturers and leveraging real-world customer feedback are key strategies that underpin confidence in choosing the right slurry pump to support industrial operations.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024