-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 20, 2025 12:25

Back to list

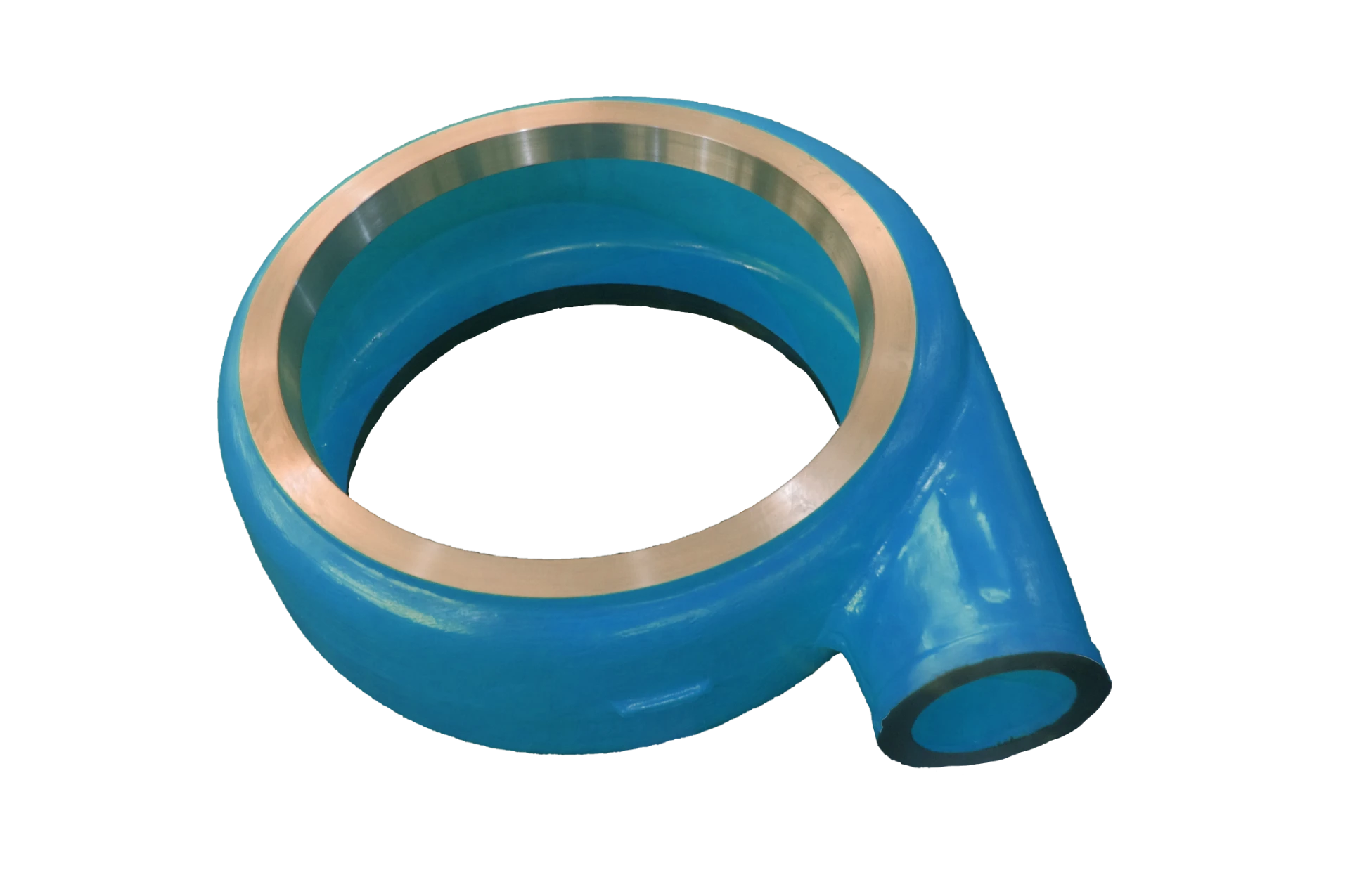

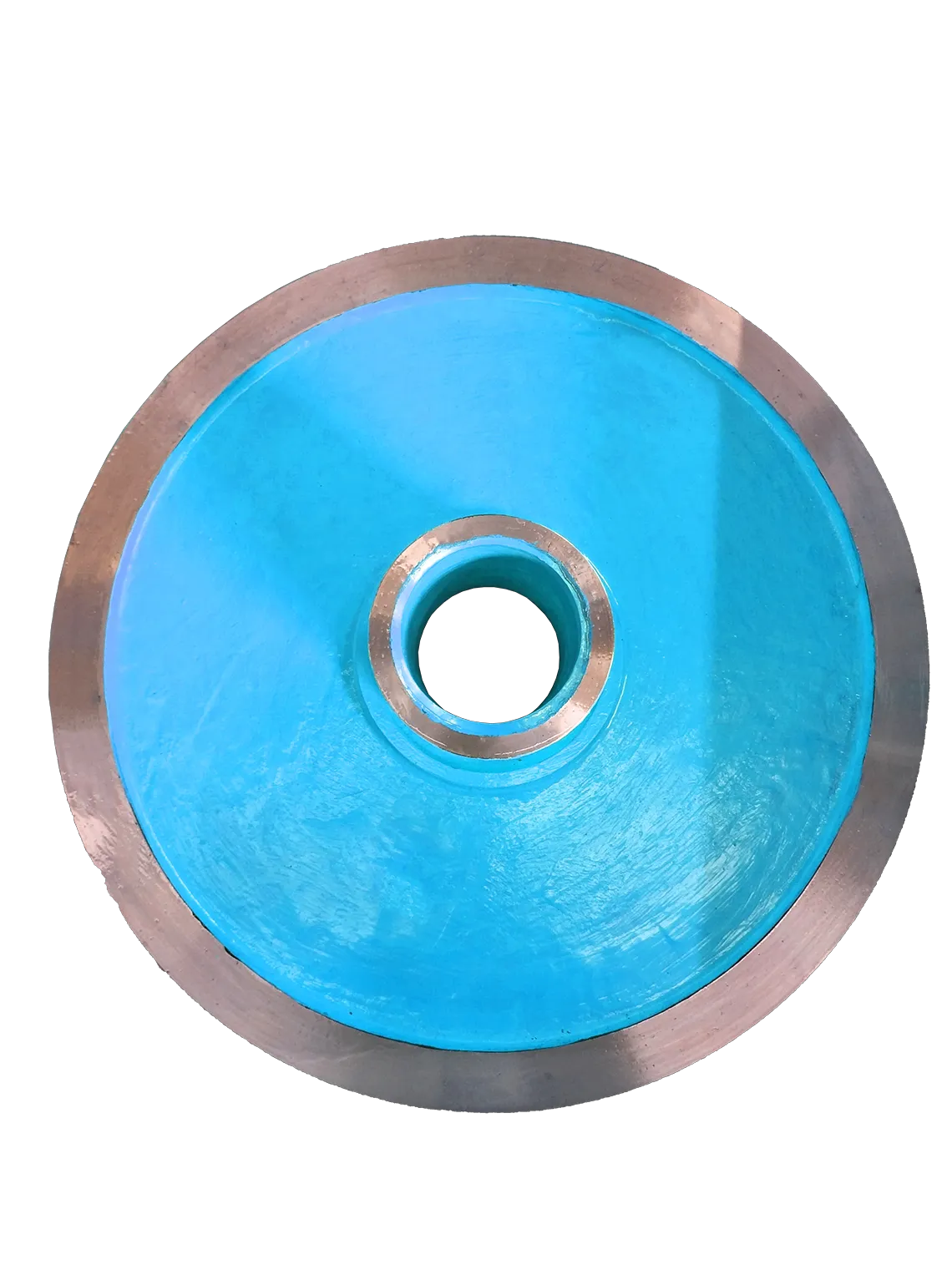

chemical slurry pump

Chemical slurry pumps are an integral component in industries where the transport of slurries is necessary. These pumps are meticulously designed to handle abrasive and corrosive slurries, which are mixtures of liquids and solid particles. Selecting the right chemical slurry pump for your application is key to maintaining operational efficiency and durability. This guide explores the essential aspects of chemical slurry pumps, offering expert insights and reliable advice for choosing and maintaining these vital industrial components.

The authority of the manufacturers providing slurry pumps also plays a significant role in ensuring quality and reliability. Selecting pumps from well-established and reputable manufacturers guarantees not only superior product quality but also access to comprehensive warranties and customer support services. Trustworthiness is built through years of innovation, compliance with industrial standards, and positive feedback from field applications. Integrating advanced technology into chemical slurry pumps has transformed their functionality and efficiency. Features such as smart monitoring systems allow for real-time analysis of pump performance, predicting potential failures before they occur. These intelligent systems are crucial for industries looking to optimize their operations and reduce unexpected downtimes. Understanding these technological advancements helps operators make informed decisions and continuously improve operational efficiency. Furthermore, chemical slurry pump users should consider the environmental impact of pump operations. Choosing energy-efficient pumps not only reduces operational costs but also minimizes the ecological footprint of industrial activities. Companies focusing on sustainability should prioritize pumps that provide maximum efficiency with minimum energy consumption, contributing to greener operations. In conclusion, chemical slurry pumps are more than just a tool for material transportation; they are pivotal to the success and sustainability of industrial processes. Understanding the intricacies of their design, material selection, and technology integration is essential for anyone seeking to enhance their industrial pumping solutions. By placing emphasis on experience, expertise, authority, and trust, industries can optimize their use of chemical slurry pumps, ensuring not only performance but also a positive contribution to their operational goals.

The authority of the manufacturers providing slurry pumps also plays a significant role in ensuring quality and reliability. Selecting pumps from well-established and reputable manufacturers guarantees not only superior product quality but also access to comprehensive warranties and customer support services. Trustworthiness is built through years of innovation, compliance with industrial standards, and positive feedback from field applications. Integrating advanced technology into chemical slurry pumps has transformed their functionality and efficiency. Features such as smart monitoring systems allow for real-time analysis of pump performance, predicting potential failures before they occur. These intelligent systems are crucial for industries looking to optimize their operations and reduce unexpected downtimes. Understanding these technological advancements helps operators make informed decisions and continuously improve operational efficiency. Furthermore, chemical slurry pump users should consider the environmental impact of pump operations. Choosing energy-efficient pumps not only reduces operational costs but also minimizes the ecological footprint of industrial activities. Companies focusing on sustainability should prioritize pumps that provide maximum efficiency with minimum energy consumption, contributing to greener operations. In conclusion, chemical slurry pumps are more than just a tool for material transportation; they are pivotal to the success and sustainability of industrial processes. Understanding the intricacies of their design, material selection, and technology integration is essential for anyone seeking to enhance their industrial pumping solutions. By placing emphasis on experience, expertise, authority, and trust, industries can optimize their use of chemical slurry pumps, ensuring not only performance but also a positive contribution to their operational goals.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024