-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 29, 2025 03:53

Back to list

centrifugal slurry pump design

The design of centrifugal slurry pumps is a meticulous process requiring precise expertise and extensive experience, given their critical role in handling abrasive and solid-laden fluids in various industries. From mining operations to waste management, these pumps are the backbone of fluid transfer systems, ensuring efficiency and durability under challenging conditions.

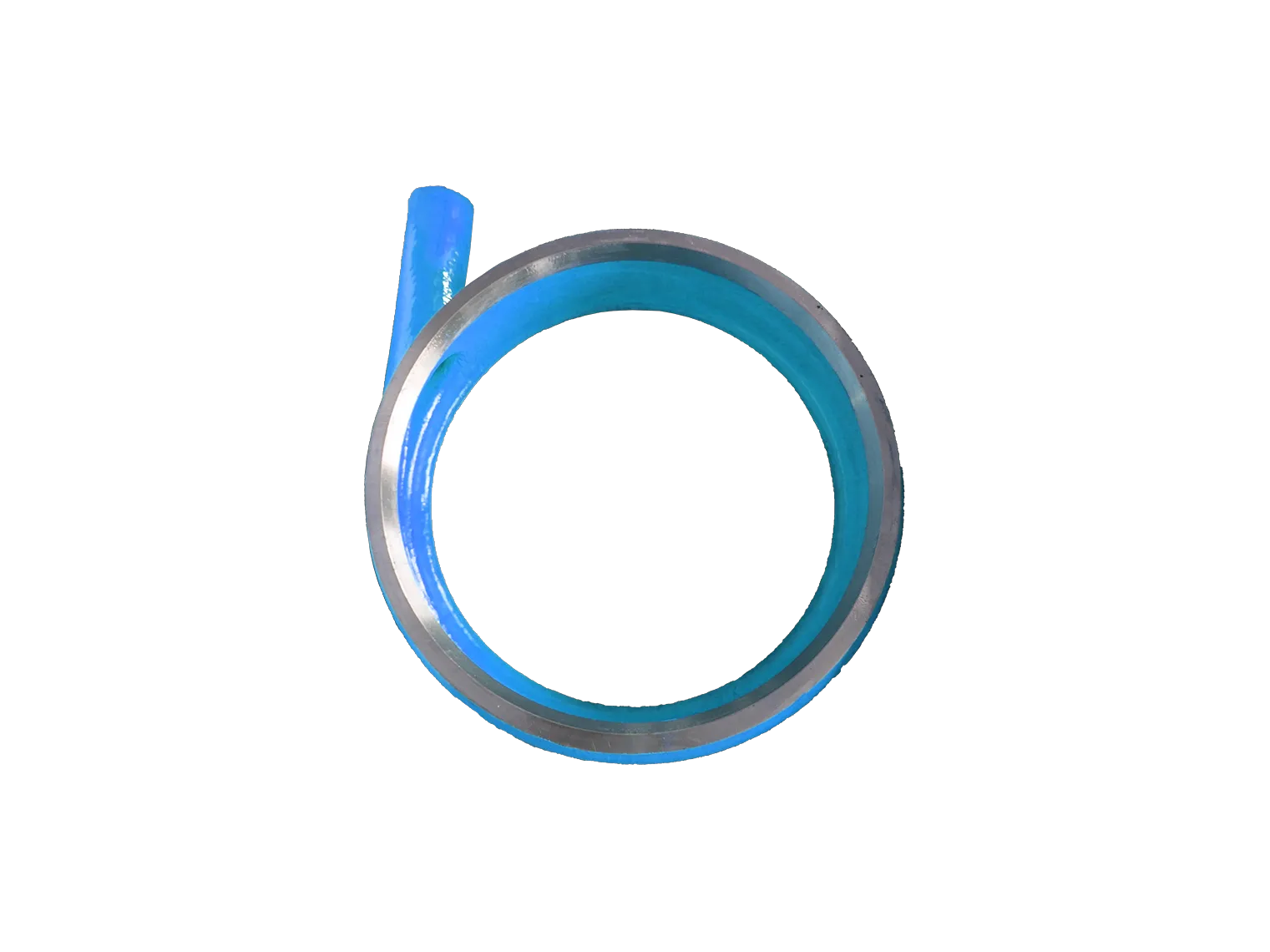

The pump seal design further reflects the expertise invested in creating centrifugal slurry pumps. Seals are engineered to prevent leakage, a crucial feature when handling hazardous or valuable materials. High-pressure sealing options and mechanical seals are tailored to specific applications, ensuring both safety and operational reliability. An authoritative design process includes prototyping and rigorous field-testing. These practices ensure that the pump performs as expected under actual working conditions. Engineers collect data from operational environments to adjust design parameters, guaranteeing that the pump meets real-world challenges with aplomb. Trustworthiness in pump design comes from transparent communication of performance data and reliability metrics. Providing detailed performance curves and case studies from verified field applications supports the customer’s decision-making process, offering assurance of the pump’s capabilities. Moreover, integrating smart technologies for monitoring pump health can enhance trust and ensure ongoing operational efficiency. Sensors tracking vibration, temperature, and wear indicate when maintenance is needed, preemptively addressing potential failures. This not only extends the pump’s service life but also aligns with contemporary trends towards intelligent and sustainable industrial solutions. In crafting centrifugal slurry pumps, manufacturers leveraging a blend of experience, specialized knowledge, and cutting-edge technology emerge as industry leaders. By focusing on material excellence, sophisticated design, and transparent customer engagement, these manufacturers reaffirm their authority and trustworthiness in the marketplace—offering products that stand the test of time and harsh operating environments.

The pump seal design further reflects the expertise invested in creating centrifugal slurry pumps. Seals are engineered to prevent leakage, a crucial feature when handling hazardous or valuable materials. High-pressure sealing options and mechanical seals are tailored to specific applications, ensuring both safety and operational reliability. An authoritative design process includes prototyping and rigorous field-testing. These practices ensure that the pump performs as expected under actual working conditions. Engineers collect data from operational environments to adjust design parameters, guaranteeing that the pump meets real-world challenges with aplomb. Trustworthiness in pump design comes from transparent communication of performance data and reliability metrics. Providing detailed performance curves and case studies from verified field applications supports the customer’s decision-making process, offering assurance of the pump’s capabilities. Moreover, integrating smart technologies for monitoring pump health can enhance trust and ensure ongoing operational efficiency. Sensors tracking vibration, temperature, and wear indicate when maintenance is needed, preemptively addressing potential failures. This not only extends the pump’s service life but also aligns with contemporary trends towards intelligent and sustainable industrial solutions. In crafting centrifugal slurry pumps, manufacturers leveraging a blend of experience, specialized knowledge, and cutting-edge technology emerge as industry leaders. By focusing on material excellence, sophisticated design, and transparent customer engagement, these manufacturers reaffirm their authority and trustworthiness in the marketplace—offering products that stand the test of time and harsh operating environments.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024