-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 28, 2025 04:02

Back to list

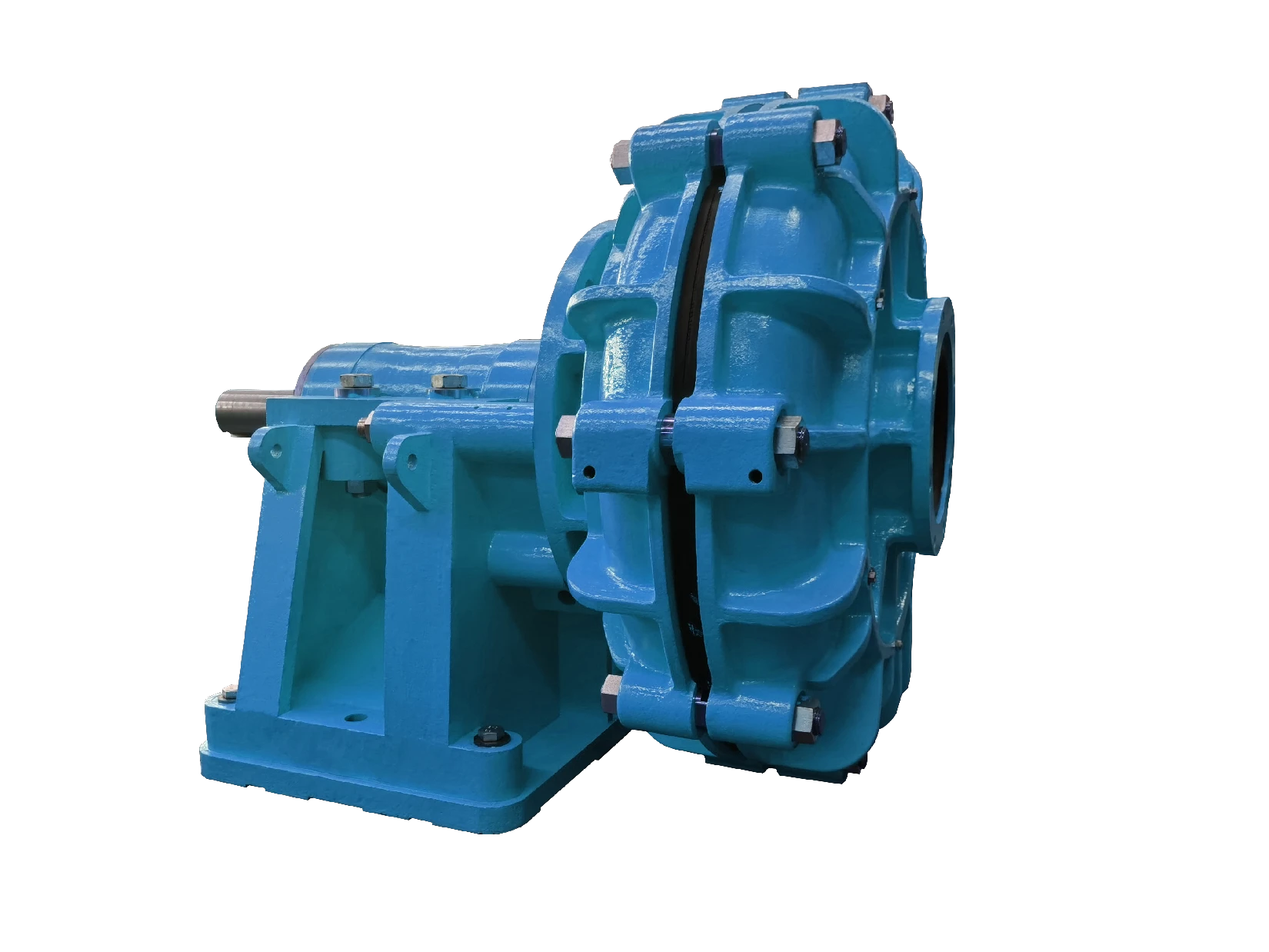

centrifugal slurry pump

Centrifugal slurry pumps are vital components in industries that handle abrasive and viscous slurry materials. Their efficiency, durability, and adaptability are critical in applications spanning mining, mineral processing, and power generation. These pumps work by converting kinetic energy into hydrodynamic energy to move slurry materials with precision and reliability.

Promises of longevity and performance excellence have to withstand the test of real-world conditions. Monitoring systems integrated into modern centrifugal slurry pumps provide critical data on performance metrics, allowing for predictive maintenance and reducing the chances of unexpected failures. Industry experts advocate for the use of digital tools to track the lifecycle of pump components, ensuring replacements are made proactively. When tackling issues related to centrifugal slurry pumps, promptly diagnosing problems is vital; optimizations can then be accurately implemented. Challenges such as cavitation, which causes considerable damage to pump components, require immediate attention. Solutions involve adjusting the pump's net positive suction head or incorporating air relief valves to mitigate pressure build-up. Environmental considerations also play a significant role in the adoption and adaptation of centrifugal slurry pumps. As industries pivot towards sustainable practices, there's an increased emphasis on developing pumps that operate efficiently under reduced carbon footprints. Manufacturers respond by introducing pumps with higher efficiency motors and variable frequency drives that adapt to fluctuating operating conditions while minimizing energy consumption. Ultimately, successful utilization of centrifugal slurry pumps is a testament to the harmonious integration of experience, expertise, authoritativeness, and trustworthiness. Industry professionals rely on a blend of theoretical knowledge and practical insights, synergistically working with the latest technological advancements to ensure optimal performance. Through dedicated research, continual professional engagement, and adaptation to market demands, centrifugal slurry pumps remain indispensable assets in managing challenging slurry environments.

Promises of longevity and performance excellence have to withstand the test of real-world conditions. Monitoring systems integrated into modern centrifugal slurry pumps provide critical data on performance metrics, allowing for predictive maintenance and reducing the chances of unexpected failures. Industry experts advocate for the use of digital tools to track the lifecycle of pump components, ensuring replacements are made proactively. When tackling issues related to centrifugal slurry pumps, promptly diagnosing problems is vital; optimizations can then be accurately implemented. Challenges such as cavitation, which causes considerable damage to pump components, require immediate attention. Solutions involve adjusting the pump's net positive suction head or incorporating air relief valves to mitigate pressure build-up. Environmental considerations also play a significant role in the adoption and adaptation of centrifugal slurry pumps. As industries pivot towards sustainable practices, there's an increased emphasis on developing pumps that operate efficiently under reduced carbon footprints. Manufacturers respond by introducing pumps with higher efficiency motors and variable frequency drives that adapt to fluctuating operating conditions while minimizing energy consumption. Ultimately, successful utilization of centrifugal slurry pumps is a testament to the harmonious integration of experience, expertise, authoritativeness, and trustworthiness. Industry professionals rely on a blend of theoretical knowledge and practical insights, synergistically working with the latest technological advancements to ensure optimal performance. Through dedicated research, continual professional engagement, and adaptation to market demands, centrifugal slurry pumps remain indispensable assets in managing challenging slurry environments.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

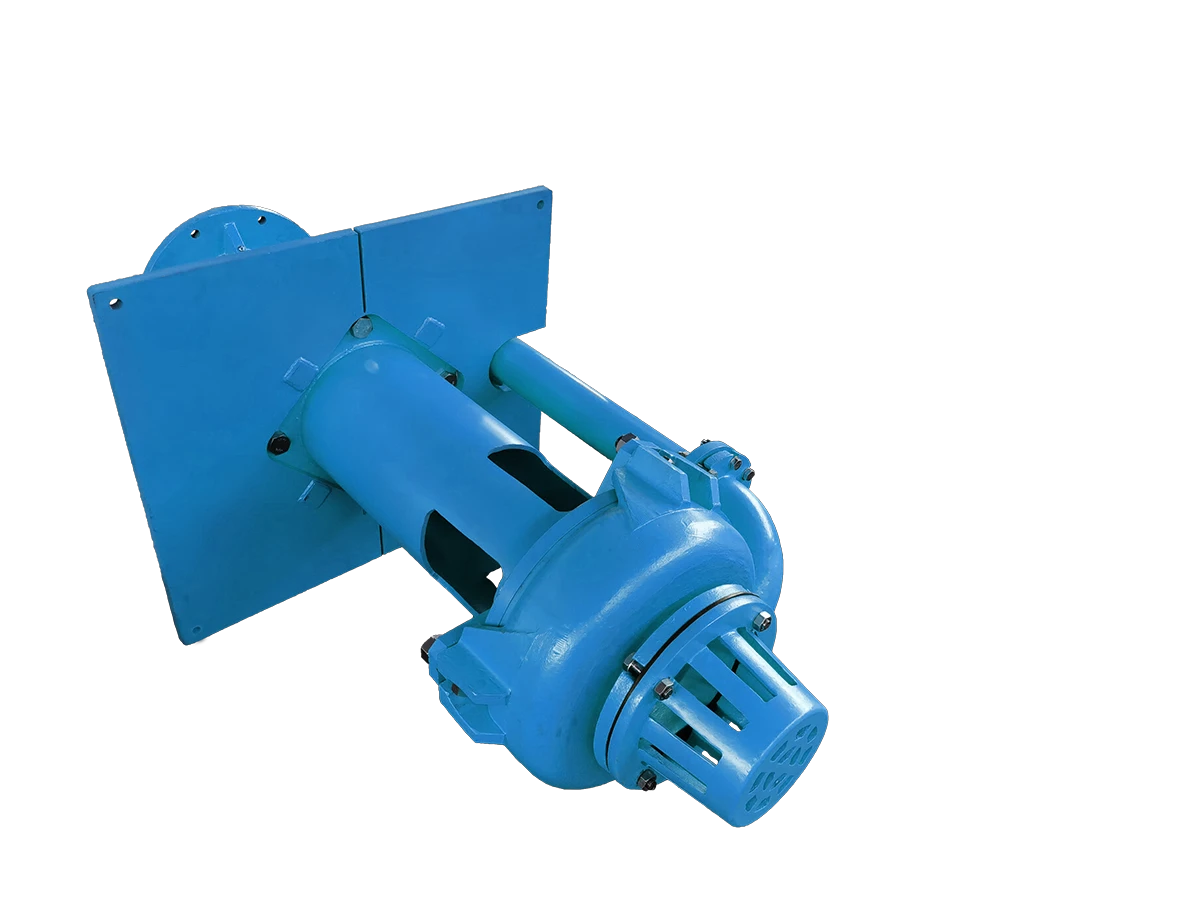

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024