-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

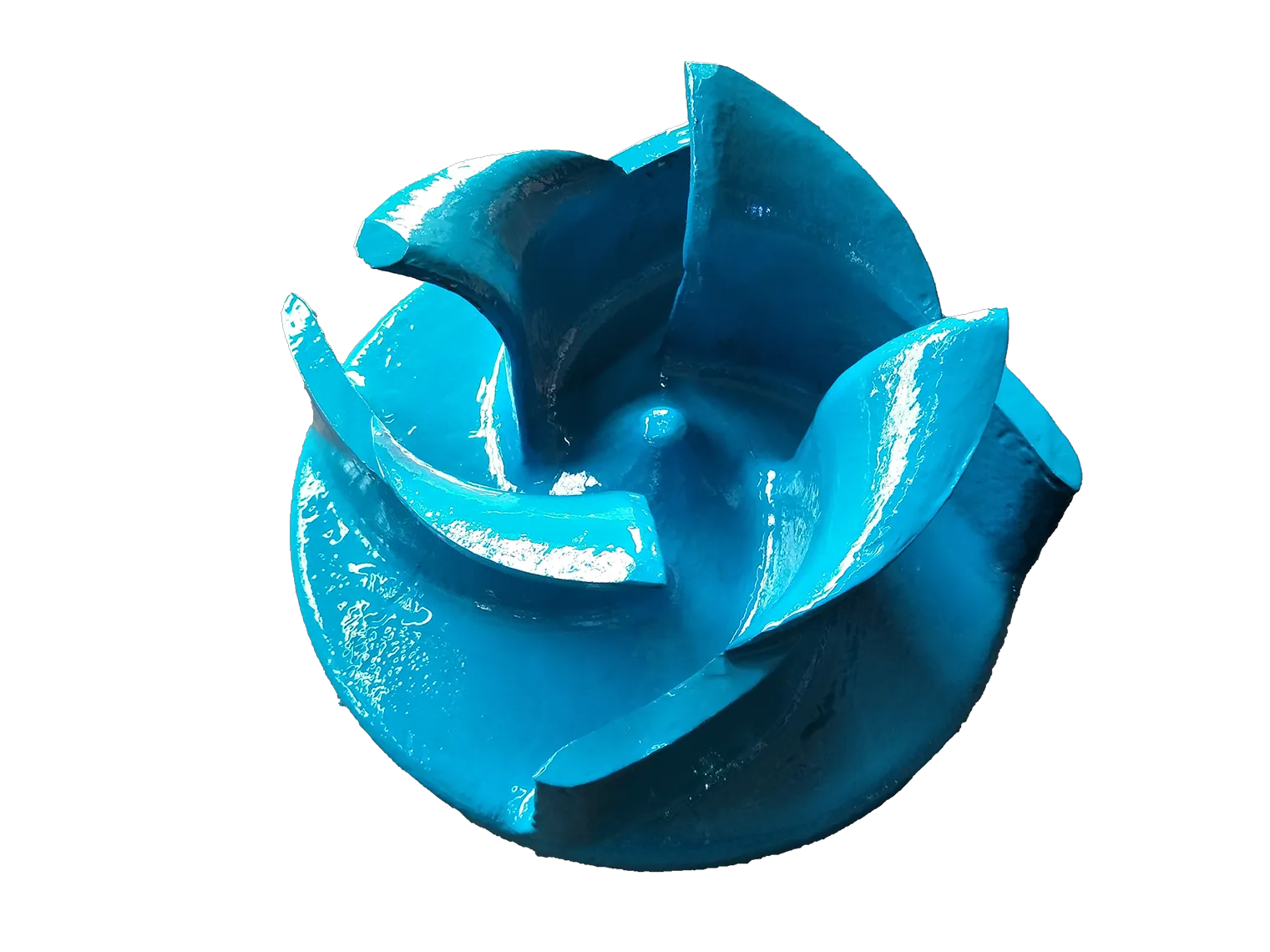

centrifugal pump wear ring

Understanding the Role of Wear Rings in Centrifugal Pumps

Centrifugal pumps are essential components in various industrial applications, providing an efficient means of transporting fluids. Among their many components, wear rings play a crucial role in ensuring optimal pump performance and longevity. In this article, we will explore the function of wear rings, the reasons for their use, and best practices for maintenance.

What are Wear Rings?

Wear rings, also known as balancing rings or clearance rings, are specifically designed components positioned between the pump impeller and the pump casing. Their primary function is to maintain a small clearance that reduces the leakage of the pumped fluid and minimizes the amount of recirculation that occurs within the pump. Typically made from materials like bronze, steel, or plastic, wear rings are capable of withstanding the wear and tear associated with the high-speed operation of centrifugal pumps.

Importance of Wear Rings

1. Minimizing Leakage One of the key purposes of wear rings is to limit the backflow of liquid that can occur from the pump discharge to the suction side. By maintaining a smaller gap, wear rings prevent excessive leakage, which can significantly affect the pump's efficiency and performance.

2. Energy Efficiency By reducing leakage, wear rings contribute to lower energy consumption. When fluid leaks back into the suction can affect the overall flow rate, causing the pump to work harder and consume more power. Efficient operation not only saves energy costs but also contributes to a reduced carbon footprint.

3. Extending Lifespan The wear rings absorb impacts and abrasions that would otherwise be detrimental to the pump casing and impeller. By acting as sacrificial components, wear rings protect more expensive and critical parts of the pump from premature wear and failure. This protective function plays a significant role in extending the overall lifespan of the pump.

4. Improved Performance Properly functioning wear rings help maintain consistent performance by ensuring optimal clearances are kept throughout the operational lifecycle of the pump. When wear rings are worn down, the clearance increases, leading to inefficiencies and fluctuations in pump performance.

centrifugal pump wear ring

Maintenance of Wear Rings

To ensure the longevity and effectiveness of wear rings, regular inspection and maintenance are essential. Here are some best practices

1. Regular Inspections Periodically check the wear rings for signs of wear and damage. Look for grooves, scoring, or discoloration, which may indicate excessive wear. Early detection of wear can prevent more serious damage to the pump.

2. Proper Lubrication If the wear rings are designed to operate with lubrication, ensure that the lubrication system is functioning correctly. Inadequate lubrication can lead to increased friction and accelerated wear.

3. Replacement Strategies Develop a replacement strategy based on the operating conditions of the pump. Factors such as the type of fluid being pumped, temperature, and pressure can all influence the rate at which wear occurs.

4. Education and Training Ensure that maintenance personnel are well-trained in the proper inspection and replacement procedures for wear rings. Understanding the importance of these components can help prevent operational downtime and costly repairs.

Conclusion

Wear rings are a vital component of centrifugal pumps that significantly impact performance, efficiency, and lifespan. By minimizing leakage, improving energy efficiency, and protecting critical parts of the pump, they play an indispensable role in fluid transportation systems. Regular maintenance and timely replacement of wear rings can enhance pump performance and prevent costly failures, ensuring that centrifugal pumps operate efficiently in various applications. Investing in proper care for wear rings can ultimately result in significant savings and improved reliability in fluid handling operations.

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024