-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 16, 2025 07:35

Back to list

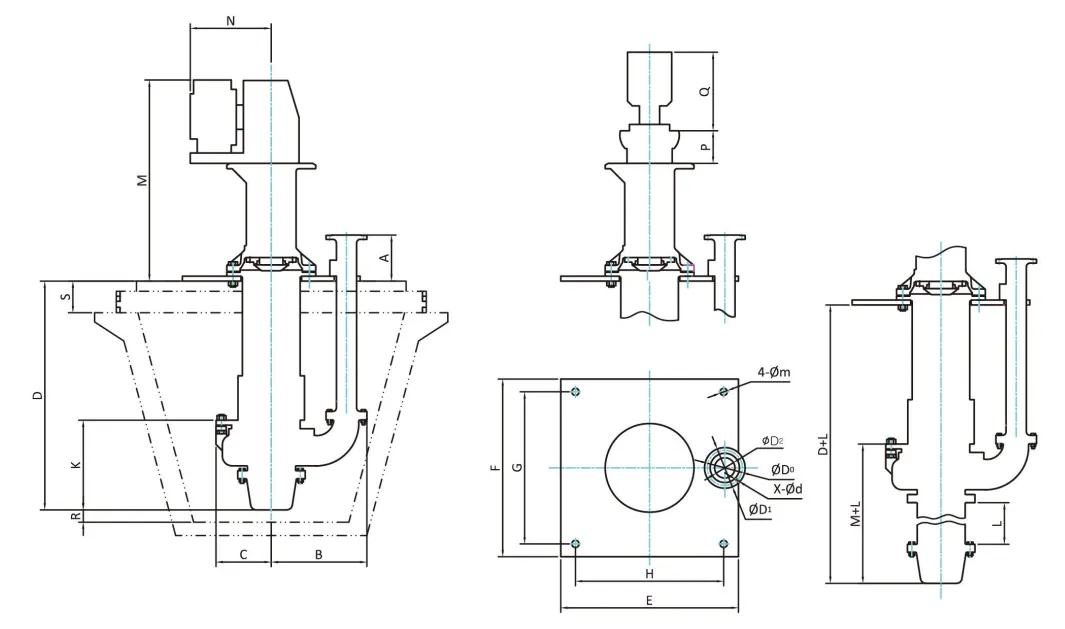

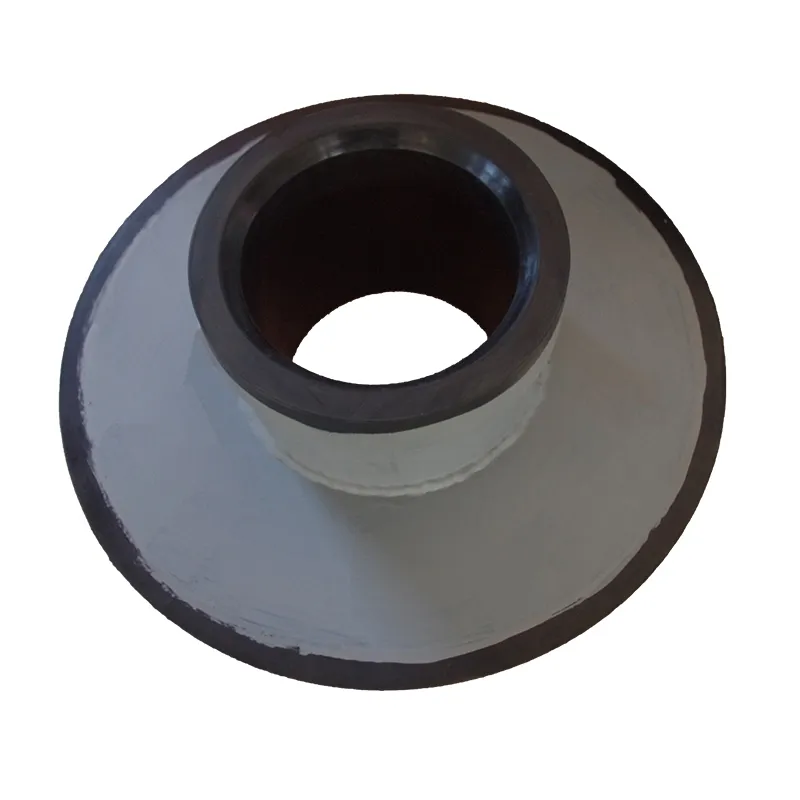

centrifugal pump volute casing design

Designing the volute casing of a centrifugal pump is a critical aspect that impacts the pump's efficiency and performance, making it a focal point for engineers and industry experts. Understanding the intricate factors that contribute to the optimal design of a volute casing is beneficial for manufacturers looking to push the boundaries of pump efficiency and reliability.

Meeting various industry standards and certifications is another critical element that contributes to the authoritativeness and trustworthiness of centrifugal pump products. Compliance with ASME, ISO, or API standards ensures that the volute casings are not only efficient but also safe and reliable under different working conditions, an aspect that customers and regulatory bodies highly regard. Moreover, integrating modern technology such as 3D printing in the prototyping phase can yield significant advantages. This technology allows for rapid iteration and testing of volute casing designs, facilitating a quicker and more precise development cycle. Engineers can experiment with complex geometries that were traditionally challenging to manufacture, paving the way for innovative design solutions that push the traditional efficiency boundaries. Documentation of empirical data from testing and real-world application further enhances the expertise and trustworthiness associated with a brand’s centrifugal pump products. Feedback from actual operational settings provides invaluable insights into volute casing design, highlighting areas for improvement and confirming theoretical design assumptions. Lastly, the collaboration between design engineers, materials scientists, and fluid dynamics experts ensures that the design process encompasses a comprehensive view of all possible operational scenarios. This multidisciplinary approach fosters innovation and precision, elevating the status of the manufacturer as a leader in centrifugal pump technology. In conclusion, the design of centrifugal pump volute casings is a complex and multifaceted task that demands high expertise and precise execution. By focusing on optimized geometry, material science, fluid dynamics, and compliance with industry standards, manufacturers can deliver products that are not only efficient but authoritative in their performance, earning trust and preference in the competitive market.

Meeting various industry standards and certifications is another critical element that contributes to the authoritativeness and trustworthiness of centrifugal pump products. Compliance with ASME, ISO, or API standards ensures that the volute casings are not only efficient but also safe and reliable under different working conditions, an aspect that customers and regulatory bodies highly regard. Moreover, integrating modern technology such as 3D printing in the prototyping phase can yield significant advantages. This technology allows for rapid iteration and testing of volute casing designs, facilitating a quicker and more precise development cycle. Engineers can experiment with complex geometries that were traditionally challenging to manufacture, paving the way for innovative design solutions that push the traditional efficiency boundaries. Documentation of empirical data from testing and real-world application further enhances the expertise and trustworthiness associated with a brand’s centrifugal pump products. Feedback from actual operational settings provides invaluable insights into volute casing design, highlighting areas for improvement and confirming theoretical design assumptions. Lastly, the collaboration between design engineers, materials scientists, and fluid dynamics experts ensures that the design process encompasses a comprehensive view of all possible operational scenarios. This multidisciplinary approach fosters innovation and precision, elevating the status of the manufacturer as a leader in centrifugal pump technology. In conclusion, the design of centrifugal pump volute casings is a complex and multifaceted task that demands high expertise and precise execution. By focusing on optimized geometry, material science, fluid dynamics, and compliance with industry standards, manufacturers can deliver products that are not only efficient but authoritative in their performance, earning trust and preference in the competitive market.

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024