-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 30, 2025 04:04

Back to list

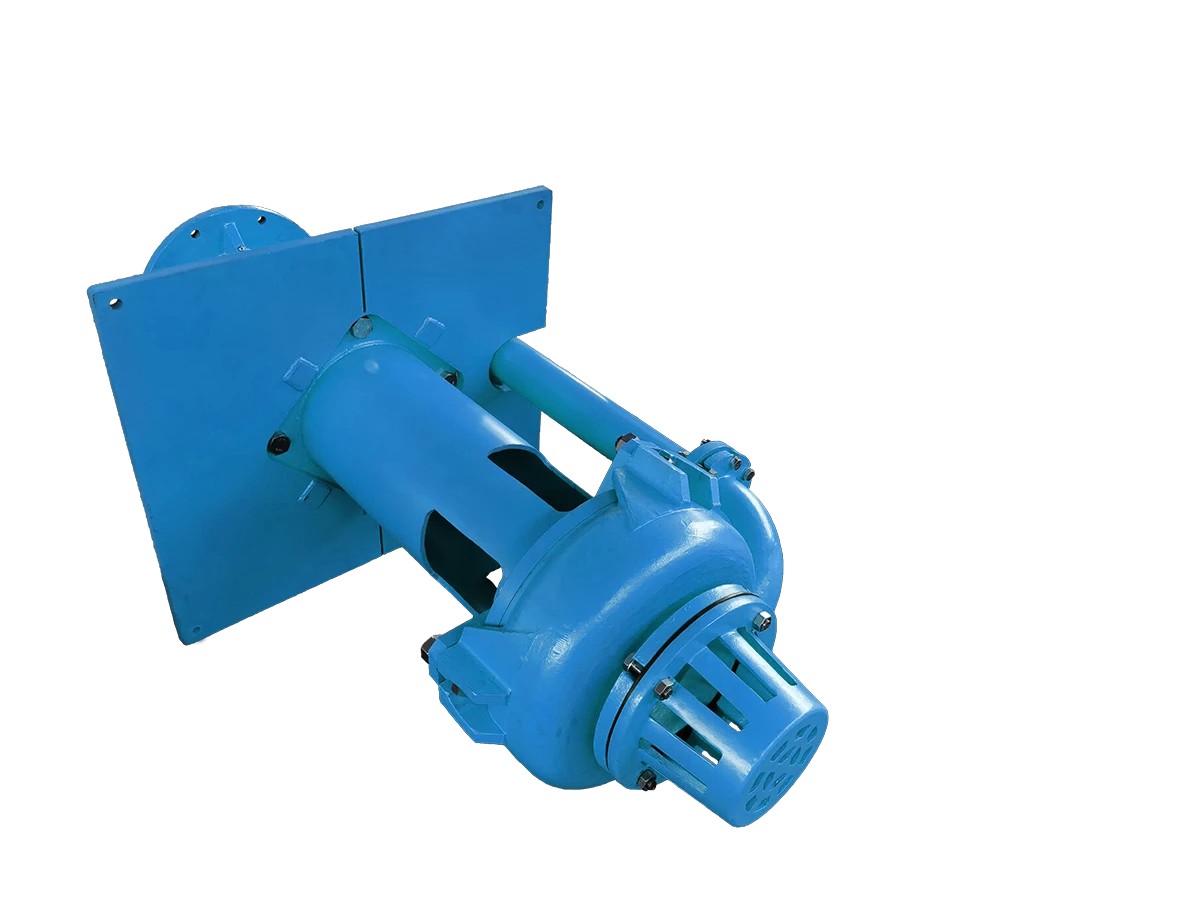

centrifugal pump vertical type

In recent years, the centrifugal pump vertical type has emerged as a critical solution for industries requiring efficient, space-saving, and reliable fluid transfer systems. As manufacturing processes become increasingly complex, the demand for versatile pumping solutions continues to grow. Vertical centrifugal pumps have proven to be a valuable asset due to their unique design and operational advantages.

Authoritative entities like the Hydraulic Institute and the American National Standards Institute frequently update their guidelines to reflect advancements in pump technology, ensuring that vertical centrifugal pumps meet rigorous safety and performance standards. Adherence to these standards offers great confidence in their reliability, supporting industries in maintaining compliance with regulatory demands. When considering the material construction, these pumps often employ high-quality, corrosion-resistant materials such as stainless steel, which enhances their suitability for corrosive and demanding environments. This adaptability makes vertical centrifugal pumps an excellent choice for the chemical, food and beverage, and waste management industries, where material integrity is critical. Trust in vertical centrifugal pumps is further solidified by their proven track record across various applications. Industries such as petroleum, HVAC, and pharmaceutical heavily rely on these pumps for their operational stability and efficiency. The ability to customize these pumps to suit specific application requirements has paved the way for tailored solutions that address unique industry challenges, thereby reinforcing their position as pivotal components in fluid handling systems. In conclusion, the vertical centrifugal pump stands out as a highly efficient, reliable, and adaptable solution for modern fluid transfer needs. Its space-saving design, high-pressure handling capabilities, and maintenance-friendly features make it a preferred choice across various industrial applications. Engineered to meet the stringent demands of contemporary standards, these pumps not only offer performance but also promote environmental sustainability, contributing to a greener future. Their widespread adoption and continuous evolution underscore their critical role in enhancing industrial efficiencies worldwide.

Authoritative entities like the Hydraulic Institute and the American National Standards Institute frequently update their guidelines to reflect advancements in pump technology, ensuring that vertical centrifugal pumps meet rigorous safety and performance standards. Adherence to these standards offers great confidence in their reliability, supporting industries in maintaining compliance with regulatory demands. When considering the material construction, these pumps often employ high-quality, corrosion-resistant materials such as stainless steel, which enhances their suitability for corrosive and demanding environments. This adaptability makes vertical centrifugal pumps an excellent choice for the chemical, food and beverage, and waste management industries, where material integrity is critical. Trust in vertical centrifugal pumps is further solidified by their proven track record across various applications. Industries such as petroleum, HVAC, and pharmaceutical heavily rely on these pumps for their operational stability and efficiency. The ability to customize these pumps to suit specific application requirements has paved the way for tailored solutions that address unique industry challenges, thereby reinforcing their position as pivotal components in fluid handling systems. In conclusion, the vertical centrifugal pump stands out as a highly efficient, reliable, and adaptable solution for modern fluid transfer needs. Its space-saving design, high-pressure handling capabilities, and maintenance-friendly features make it a preferred choice across various industrial applications. Engineered to meet the stringent demands of contemporary standards, these pumps not only offer performance but also promote environmental sustainability, contributing to a greener future. Their widespread adoption and continuous evolution underscore their critical role in enhancing industrial efficiencies worldwide.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024