-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 14, 2025 09:44

Back to list

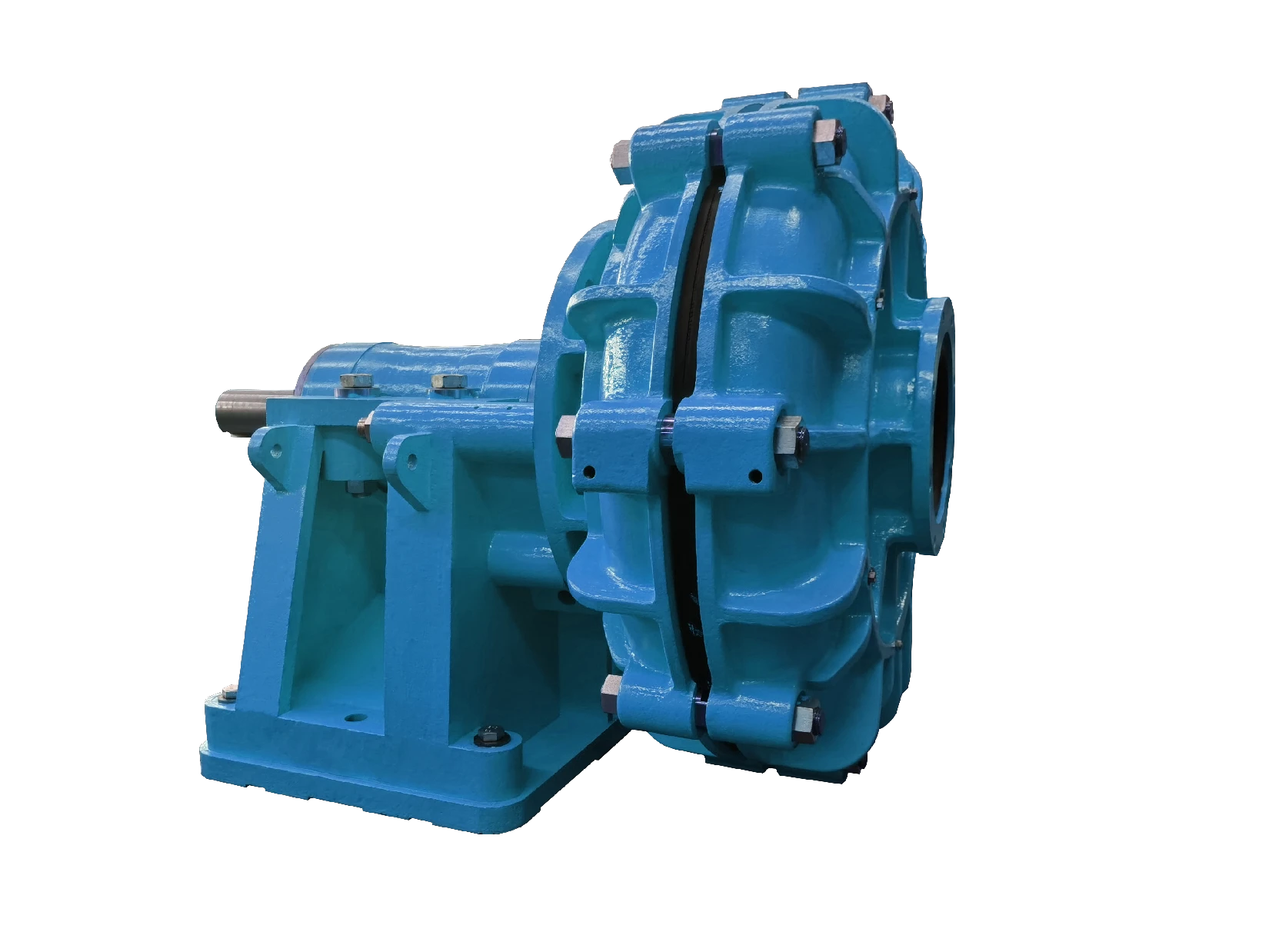

centrifugal pump vane design

Centrifugal pump vane design is a critical component in the efficiency and longevity of pumps used across various industries. These pumps play an essential role in moving fluids through pipelines and processing systems, and the design of their vanes has a direct impact on performance metrics such as flow rate, pressure head, and energy consumption.

Material selection is another crucial aspect of vane design. Depending on the fluid's properties, materials ranging from stainless steel to specialized polymers are used to ensure durability and resistance to wear and corrosion. This trustworthiness in material choice extends the pump's service life and assures clients of a reliable pumping solution. Additionally, vane design must adhere to industry standards and regulations, which serve as benchmarks for quality and safety. Compliance with these standards, coupled with third-party certifications, enhances the pump's credibility, creating additional layers of trust with clients and partners. The evolution of smart sensor technology has further impacted centrifugal pump design, allowing for real-time monitoring of pump performance. Sensors can detect deviations in operation that signal wear or failure of the vanes, enabling timely maintenance and avoiding costly downtime. This innovative use of technology underscores the importance of combining traditional engineering expertise with cutting-edge advancements, ensuring the centrifugal pump remains a trustworthy and high-performance product. In conclusion, centrifugal pump vane design is a multifaceted field that bridges fluid dynamics and material science to produce efficient, reliable pumps. By investing in research and harnessing advanced technologies such as CFD and smart sensors, manufacturers can optimize pump performance, reduce energy consumption, and minimize operational costs. As demand for more efficient and sustainable solutions grows, the expertise and authority of pump designers become increasingly vital, solidifying their role as key contributors to industrial progress and innovation.

Material selection is another crucial aspect of vane design. Depending on the fluid's properties, materials ranging from stainless steel to specialized polymers are used to ensure durability and resistance to wear and corrosion. This trustworthiness in material choice extends the pump's service life and assures clients of a reliable pumping solution. Additionally, vane design must adhere to industry standards and regulations, which serve as benchmarks for quality and safety. Compliance with these standards, coupled with third-party certifications, enhances the pump's credibility, creating additional layers of trust with clients and partners. The evolution of smart sensor technology has further impacted centrifugal pump design, allowing for real-time monitoring of pump performance. Sensors can detect deviations in operation that signal wear or failure of the vanes, enabling timely maintenance and avoiding costly downtime. This innovative use of technology underscores the importance of combining traditional engineering expertise with cutting-edge advancements, ensuring the centrifugal pump remains a trustworthy and high-performance product. In conclusion, centrifugal pump vane design is a multifaceted field that bridges fluid dynamics and material science to produce efficient, reliable pumps. By investing in research and harnessing advanced technologies such as CFD and smart sensors, manufacturers can optimize pump performance, reduce energy consumption, and minimize operational costs. As demand for more efficient and sustainable solutions grows, the expertise and authority of pump designers become increasingly vital, solidifying their role as key contributors to industrial progress and innovation.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024