-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 12, 2025 21:17

Back to list

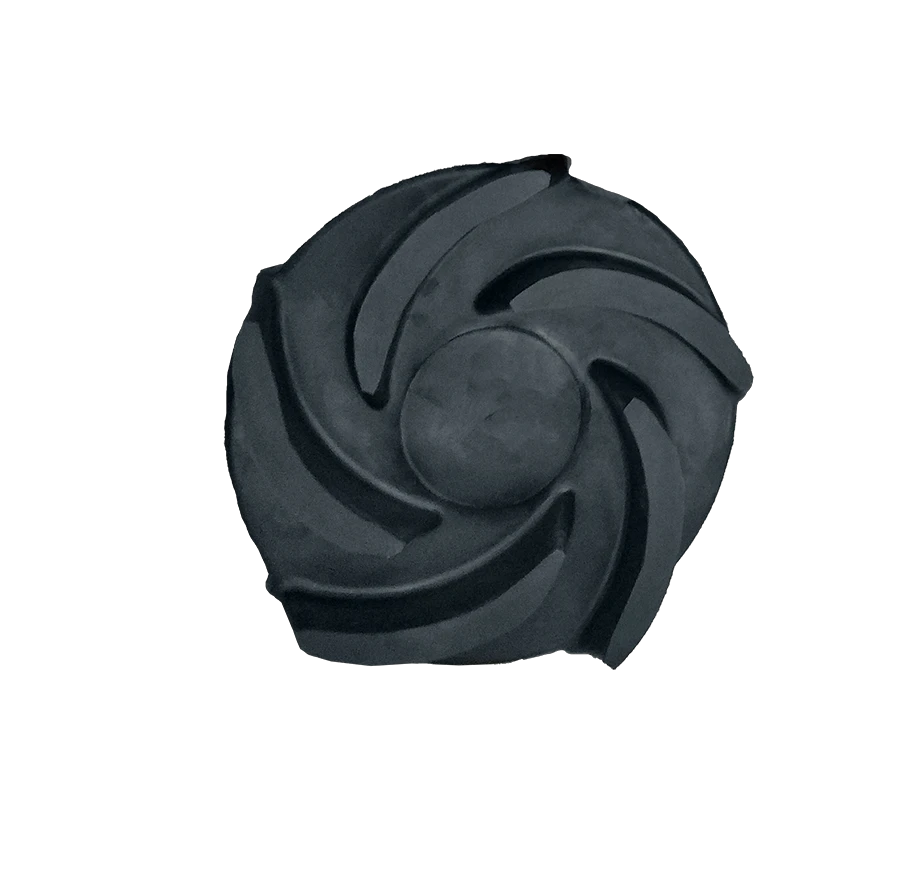

centrifugal pump rotor

The centrifugal pump rotor plays a pivotal role in the efficient operation and reliability of centrifugal pumps, commonly used across various industries such as oil and gas, water treatment, and chemical processing. Understanding the nuances of centrifugal pump rotors can significantly enhance performance and ensure longevity.

Regular maintenance and inspection play a crucial role in sustaining rotor performance. Implementing a proactive maintenance schedule helps identify wear and tear early, preventing severe malfunctions. Regular inspections should focus on detecting signs of erosion, corrosion, and thermal degradation, which might affect the rotor's structural integrity. Utilizing non-destructive testing methods such as ultrasonic testing or dye penetrant inspection can effectively identify subsurface defects without dismantling the pump. Authoritativeness in centrifugal pump rotor management involves adhering to industry standards and guidelines such as those set by the Hydraulic Institute or ISO standards, which specify performance criteria and testing procedures. Incorporating these standards into the design and operational practices ensures that the centrifugal pump operates within acceptable performance parameters, enhancing safety and reliability. Trustworthiness in handling centrifugal pump rotors is augmented by partnering with experienced manufacturers and suppliers renowned for high-quality components. A reliable partner not only supplies top-grade materials but also provides technical support and warranties, ensuring that the rotor performs efficiently throughout its service life. Innovations in rotor design are continually emerging, driven by the need for energy efficiency and reduced operating costs. Magnetic bearings, for instance, are being explored to eliminate mechanical contact, thereby reducing friction and wear. Similarly, advancements in 3D printing technology allow for customized rotor designs tailored to specific applications, optimizing fluid dynamics and minimizing energy wastage. In conclusion, the centrifugal pump rotor is a critical component demanding careful consideration of design, material selection, and maintenance practices. By leveraging expertise and adhering to established standards, industries can ensure their centrifugal pumps operate efficiently, reliably, and economically, harnessing the full potential of technological advancements. Such diligent management not only fosters operational excellence but also contributes to sustainable industrial practices, highlighting the indispensable role of the centrifugal pump rotor in modern engineering.

Regular maintenance and inspection play a crucial role in sustaining rotor performance. Implementing a proactive maintenance schedule helps identify wear and tear early, preventing severe malfunctions. Regular inspections should focus on detecting signs of erosion, corrosion, and thermal degradation, which might affect the rotor's structural integrity. Utilizing non-destructive testing methods such as ultrasonic testing or dye penetrant inspection can effectively identify subsurface defects without dismantling the pump. Authoritativeness in centrifugal pump rotor management involves adhering to industry standards and guidelines such as those set by the Hydraulic Institute or ISO standards, which specify performance criteria and testing procedures. Incorporating these standards into the design and operational practices ensures that the centrifugal pump operates within acceptable performance parameters, enhancing safety and reliability. Trustworthiness in handling centrifugal pump rotors is augmented by partnering with experienced manufacturers and suppliers renowned for high-quality components. A reliable partner not only supplies top-grade materials but also provides technical support and warranties, ensuring that the rotor performs efficiently throughout its service life. Innovations in rotor design are continually emerging, driven by the need for energy efficiency and reduced operating costs. Magnetic bearings, for instance, are being explored to eliminate mechanical contact, thereby reducing friction and wear. Similarly, advancements in 3D printing technology allow for customized rotor designs tailored to specific applications, optimizing fluid dynamics and minimizing energy wastage. In conclusion, the centrifugal pump rotor is a critical component demanding careful consideration of design, material selection, and maintenance practices. By leveraging expertise and adhering to established standards, industries can ensure their centrifugal pumps operate efficiently, reliably, and economically, harnessing the full potential of technological advancements. Such diligent management not only fosters operational excellence but also contributes to sustainable industrial practices, highlighting the indispensable role of the centrifugal pump rotor in modern engineering.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024