-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

Understanding the Functionality of Centrifugal Pump Rotor in Fluid Dynamics Applications

Understanding Centrifugal Pump Rotors Design, Function, and Applications

Centrifugal pumps are essential devices in various industries, ensuring fluid movement with efficiency and reliability. At the heart of these pumps lies the rotor, a critical component that defines the pump's performance and operational characteristics. This article explores the design, function, and applications of centrifugal pump rotors.

The Design of Centrifugal Pump Rotors

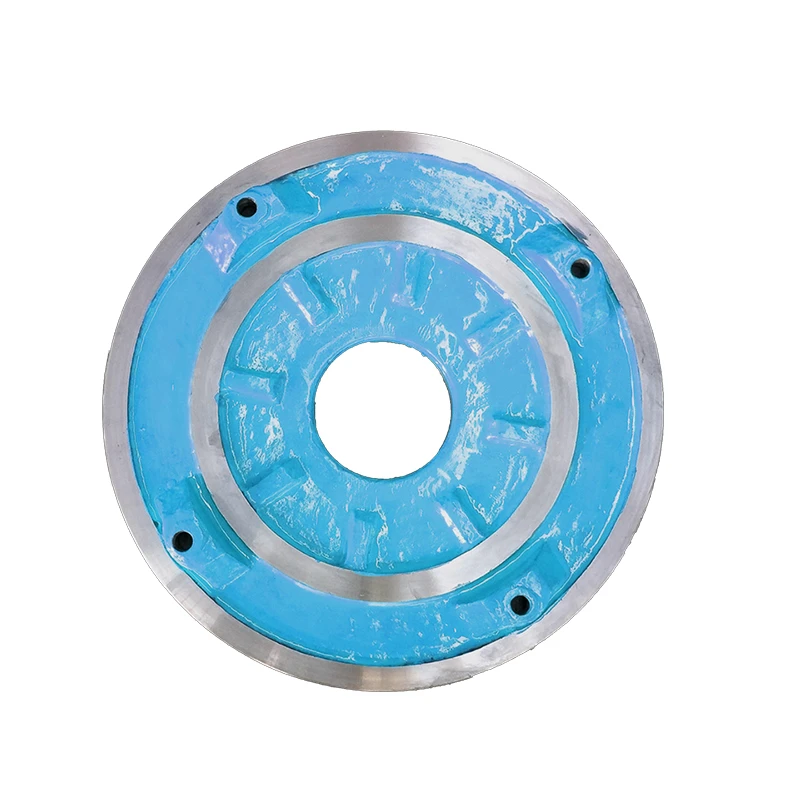

The rotor of a centrifugal pump typically consists of a series of blades or impellers mounted on a shaft. These blades are designed to create a centrifugal force when the rotor is spun. The design of the rotor is crucial because it impacts fluid dynamics, including flow rate, pressure, and energy efficiency.

Rotors can be categorized into two main types open and closed impellers. Open impellers have blades that are not enclosed by a shroud, making them more suitable for handling fluids with larger particles. Closed impellers, on the other hand, are encased and provide better efficiency and pressure generation. The choice between these designs often depends on the specific applications and the nature of the fluids being pumped.

Functionality of the Rotor

When the rotor spins, it accelerates the fluid outward, transforming kinetic energy into pressure energy. This mechanism is central to the operation of centrifugal pumps. The rotor not only moves the fluid but also directs it towards the pump's discharge. As liquid enters the eye of the rotor, it is grabbed by the impeller blades and propelled outward by centrifugal force, which increases its velocity.

As the fluid exits the impeller, it enters a volute or diffuser section, where its high kinetic energy is converted into pressure. The geometry of the volute plays a significant role in this process, as it helps smooth the flow and reduce turbulence, ultimately leading to efficient energy transfer. The design and material of the rotor also play a significant role in preventing wear and corrosion, ensuring longevity and performance stability.

centrifugal pump rotor

Applications of Centrifugal Pump Rotors

Centrifugal pump rotors find applications across various sectors including water treatment, chemical processing, oil and gas, and HVAC systems. In water treatment facilities, for instance, these pumps are used to transport large volumes of water quickly, essential for maintaining supply and controlling processes. In the oil and gas industry, centrifugal pumps are often employed for the movement of crude oil and refined products, where the reliable performance of the rotor ensures continuous operation.

Furthermore, in manufacturing plants, centrifugal pumps equipped with robust rotors handle viscous fluids, slurries, and chemically aggressive liquids, showcasing the versatility of rotor designs. Each application may require specific rotor configurations and materials to handle varying fluid dynamics and environmental conditions.

Future Trends in Rotor Development

The development of centrifugal pump rotors continues to evolve with advancements in materials and technology. Manufacturers are increasingly focusing on energy efficiency and sustainability, leading to the design of rotors that optimize performance while minimizing energy consumption. Innovations such as computational fluid dynamics (CFD) modeling aid engineers in refining rotor shapes for improved hydraulic performance and reduced cavitation risk.

Additionally, the integration of smart technology in pump systems allows for real-time monitoring of rotor performance, providing data that can enhance predictive maintenance and operational adjustments.

Conclusion

In conclusion, the centrifugal pump rotor is a vital element that directly influences the pump's efficiency, performance, and suitability for various applications. As industries continue to evolve and demand more efficient pumping solutions, the design and functionality of rotors will remain at the forefront of engineering innovations, making centrifugal pumps a pivotal component in fluid management systems. Understanding the nuances of rotor design can lead to better choices in both industrial applications and facility management, ultimately improving operational efficiency and sustainability.

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024