-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 14, 2025 08:49

Back to list

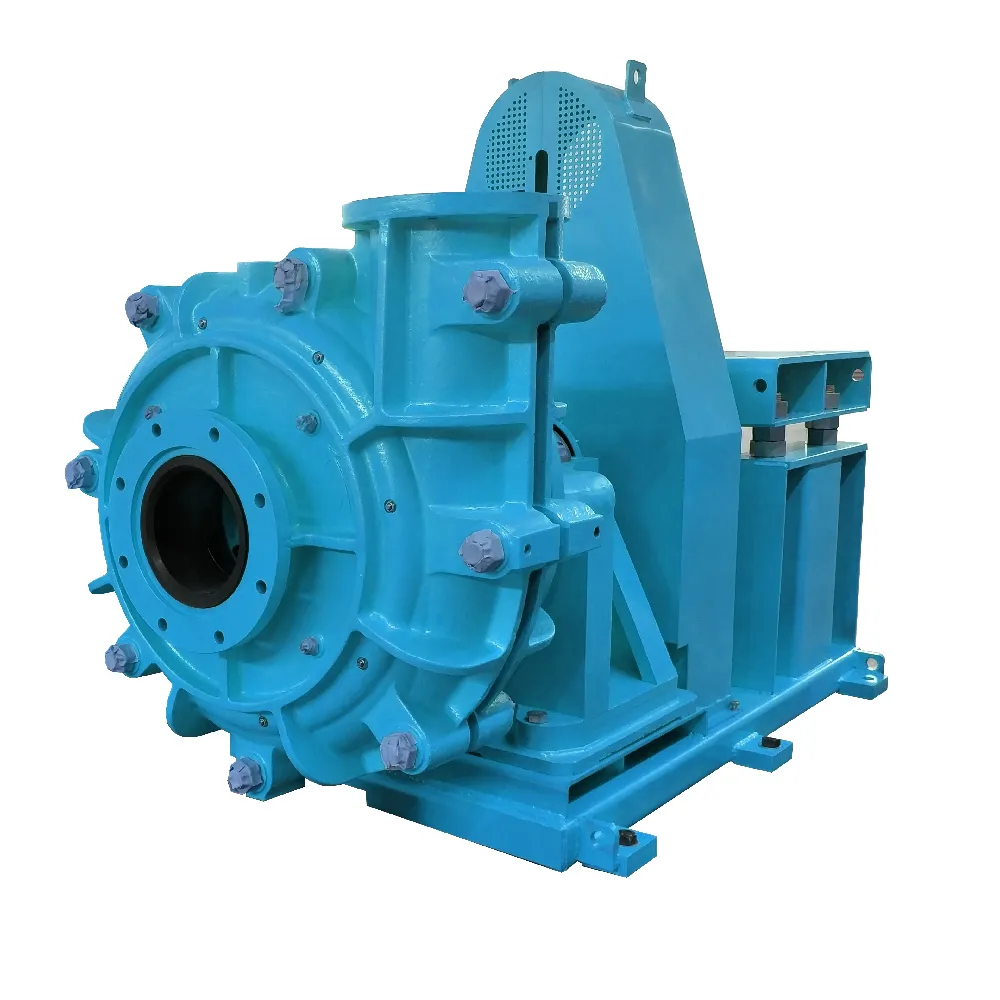

centrifugal pump blade design

The intricacies of centrifugal pump blade design play a pivotal role in the efficiency and effectiveness of fluid handling operations. In the dynamic field of engineering, the adaptability and innovation within centrifugal pump technology underscore its indispensable utility across varied industries—from chemical processing to water treatment. This article explores the nuanced aspects of centrifugal pump blade design through a lens of experience, expertise, authoritativeness, and trustworthiness, catering to those invested in superior product efficacy.

In practice, trustworthiness is cultivated through transparent sharing of design methodologies and documented success stories. Case studies of pumps operating in extreme environments demonstrate resilience and adaptability, two qualities vital to establishing customer trust. Documentation of rigorous testing processes, alongside testimonials from satisfied users, further solidifies a design's credibility. Effective centrifugal pump blade design, therefore, hinges on a confluence of theoretical knowledge and practical application. Diverse industries benefit from designs that harness cutting-edge technology and rigorous analytical methods, resulting in components that exceed performance expectations. As technology advances, the incorporation of artificial intelligence and machine learning into the design process is becoming commonplace, revolutionizing traditionally manual optimizations. These technologies streamline complex calculations, rapidly produce design iterations, and predict performance outcomes with unprecedented accuracy. Ultimately, the future of centrifugal pump design is defined by sustainable innovation and commitment to excellence. As industry needs evolve, so too must the approaches, materials, and technologies employed by engineers, maintaining an unwavering focus on efficiency, reliability, and environmental impact. The sophisticated blend of experience-led insights and authoritative frameworks is integral, not only in meeting today's demands but in actively shaping the fluid-handling solutions of tomorrow.

In practice, trustworthiness is cultivated through transparent sharing of design methodologies and documented success stories. Case studies of pumps operating in extreme environments demonstrate resilience and adaptability, two qualities vital to establishing customer trust. Documentation of rigorous testing processes, alongside testimonials from satisfied users, further solidifies a design's credibility. Effective centrifugal pump blade design, therefore, hinges on a confluence of theoretical knowledge and practical application. Diverse industries benefit from designs that harness cutting-edge technology and rigorous analytical methods, resulting in components that exceed performance expectations. As technology advances, the incorporation of artificial intelligence and machine learning into the design process is becoming commonplace, revolutionizing traditionally manual optimizations. These technologies streamline complex calculations, rapidly produce design iterations, and predict performance outcomes with unprecedented accuracy. Ultimately, the future of centrifugal pump design is defined by sustainable innovation and commitment to excellence. As industry needs evolve, so too must the approaches, materials, and technologies employed by engineers, maintaining an unwavering focus on efficiency, reliability, and environmental impact. The sophisticated blend of experience-led insights and authoritative frameworks is integral, not only in meeting today's demands but in actively shaping the fluid-handling solutions of tomorrow.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024