-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 12, 2025 20:19

Back to list

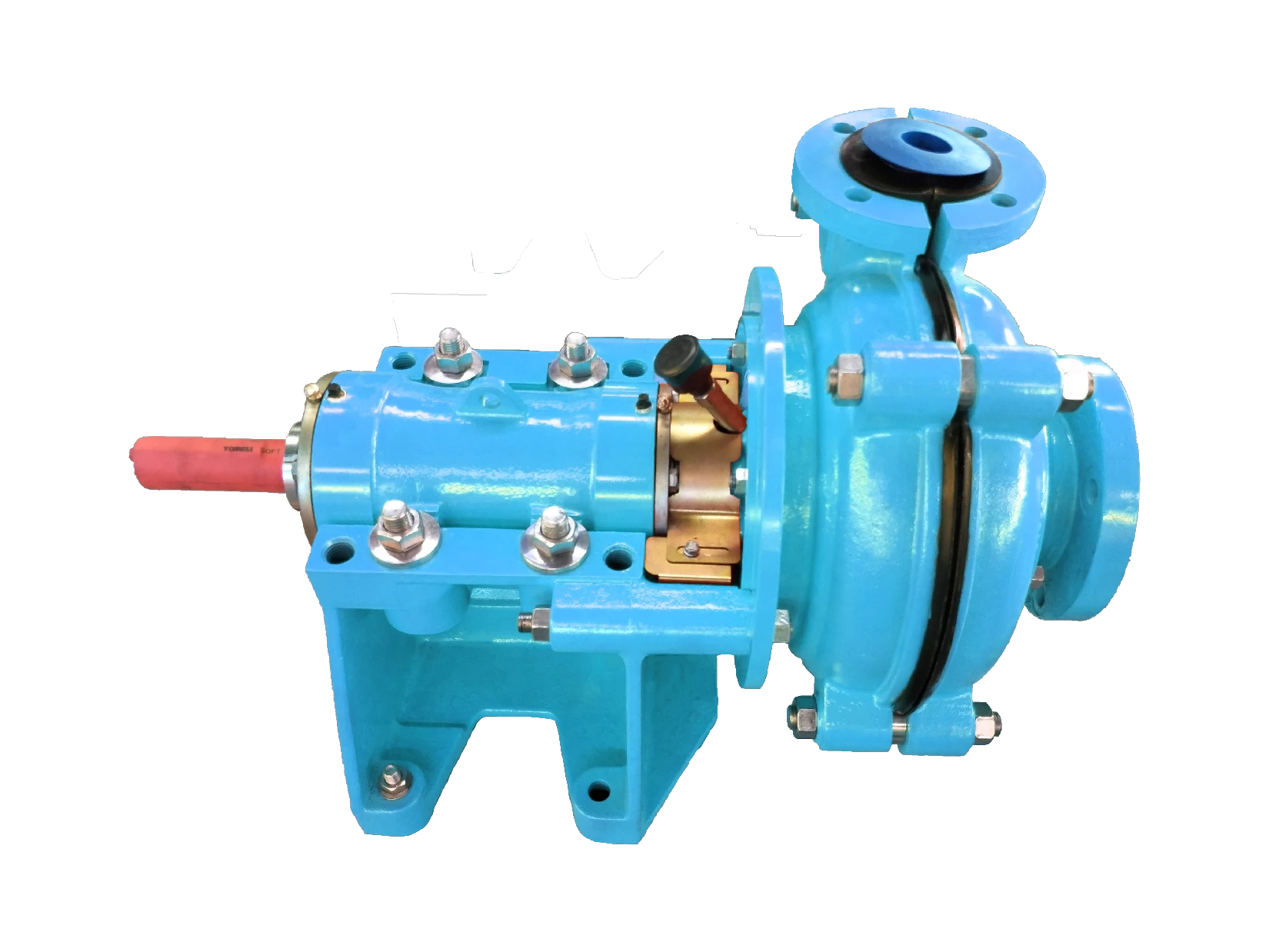

centrifugal pump blade

The efficiency and reliability of centrifugal pumps are significantly influenced by the design and condition of their blades. These components are crucial in transforming the mechanical energy into fluid movement, thereby ensuring optimal performance in various applications ranging from water treatment to industrial fluid handling.

Innovations in centrifugal pump blades are continually evolving. One emerging trend is the use of digital twin technology, where a virtual model of the pump and its blades are created to simulate and predict real-world behavior. This approach allows for real-time monitoring and adjustments, potentially reducing downtime and maintenance costs. Furthermore, 3D printing technology is beginning to be explored as a viable method for producing complex blade geometries that were previously difficult or impossible to manufacture using traditional methods. Centrifugal pump blades also play a significant role in environmental considerations. Properly designed and maintained blades can contribute to reduced energy consumption, thereby lowering greenhouse gas emissions from pump operations. This is increasingly important as industries strive to meet stringent environmental regulations and sustainability goals. Additionally, longer-lasting blades reduce the frequency of replacements, minimizing waste and the environmental impact associated with manufacturing and disposal. Incorporating expertise and leveraging technological advancements in blade design and materials are critical for optimizing centrifugal pump performance. Manufacturers and engineers must collaborate closely, using evidence-based practices and cutting-edge technologies, to develop blades that meet the specific demands of varied applications while maintaining cost-effectiveness. Ultimately, the key to maximizing the potential of centrifugal pump blades lies in understanding the intricate balance between design, material, and application-specific needs. With ongoing advancements in engineering and materials science, the future holds promising possibilities for even more efficient and durable centrifugal pump designs. Investing in the right technologies and maintaining a proactive approach to blade management is essential for any organization seeking to enhance its pumping systems' performance and reliability, ensuring continued operational success and sustainability.

Innovations in centrifugal pump blades are continually evolving. One emerging trend is the use of digital twin technology, where a virtual model of the pump and its blades are created to simulate and predict real-world behavior. This approach allows for real-time monitoring and adjustments, potentially reducing downtime and maintenance costs. Furthermore, 3D printing technology is beginning to be explored as a viable method for producing complex blade geometries that were previously difficult or impossible to manufacture using traditional methods. Centrifugal pump blades also play a significant role in environmental considerations. Properly designed and maintained blades can contribute to reduced energy consumption, thereby lowering greenhouse gas emissions from pump operations. This is increasingly important as industries strive to meet stringent environmental regulations and sustainability goals. Additionally, longer-lasting blades reduce the frequency of replacements, minimizing waste and the environmental impact associated with manufacturing and disposal. Incorporating expertise and leveraging technological advancements in blade design and materials are critical for optimizing centrifugal pump performance. Manufacturers and engineers must collaborate closely, using evidence-based practices and cutting-edge technologies, to develop blades that meet the specific demands of varied applications while maintaining cost-effectiveness. Ultimately, the key to maximizing the potential of centrifugal pump blades lies in understanding the intricate balance between design, material, and application-specific needs. With ongoing advancements in engineering and materials science, the future holds promising possibilities for even more efficient and durable centrifugal pump designs. Investing in the right technologies and maintaining a proactive approach to blade management is essential for any organization seeking to enhance its pumping systems' performance and reliability, ensuring continued operational success and sustainability.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024