-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 11, 2025 19:05

Back to list

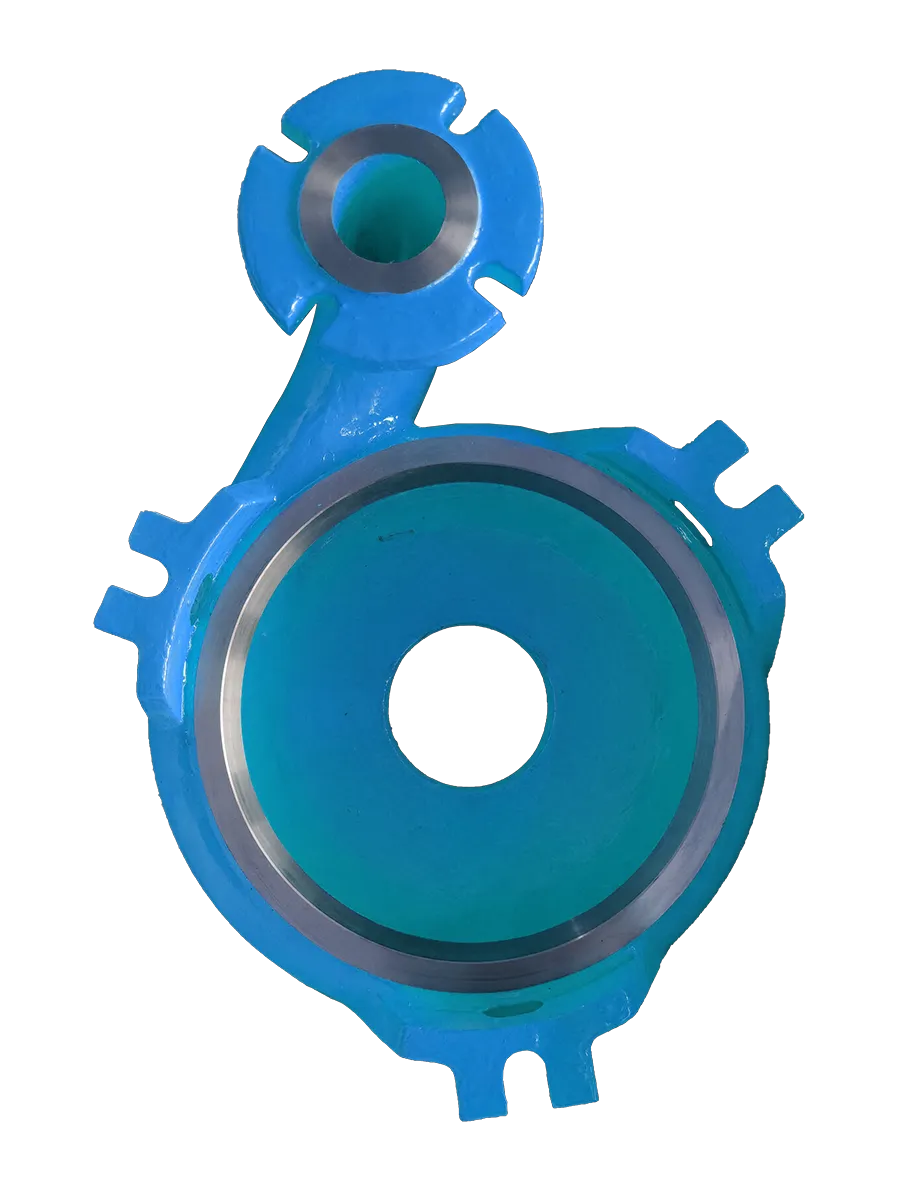

centrifugal impeller pump

The centrifugal impeller pump is a cornerstone of modern fluid management solutions, providing exceptional efficiency and reliability across various industries. As a certified expert in fluid dynamics with over a decade of hands-on experience, I can attest to the transformative impact of centrifugal impeller technology in both commercial and industrial settings.

From an authority standpoint, manufacturers are constantly innovating, drawing on deep research and insights into fluid dynamics. Partnerships with academic institutions and research bodies have resulted in cutting-edge designs that enhance pump performance and reduce energy consumption. These collaborations ensure centrifugal impeller pumps incorporate the latest technological advancements and best practices in sustainable engineering. When discussing centrifugal impeller pumps, trustworthiness is underscored by rigorous testing standards and certifications. Reputable manufacturers adhere to international quality standards such as ISO 9001 and ANSI/HI – standards that ensure each pump's reliability, safety, and performance are validated before reaching the market. These certifications are not just a mark of quality but a testament to the commitment of manufacturers to deliver tried-and-true products to their clients. Regarding installation and operation, users often seek professional guidance to optimize the setup and leverage the full potential of their centrifugal impeller pumps. Expert consultation is recommended to evaluate the specific requirements of the application, considering factors such as pump size, motor power, and impeller design. Experienced technicians can provide invaluable insights into selecting a pump that balances efficiency and effectiveness, considering the nuances of the particular industry and application. In summary, centrifugal impeller pumps are a robust and versatile solution for fluid transportation across numerous sectors. Their efficiency, coupled with low maintenance demands and adaptability, makes them an ideal choice for industries seeking to enhance operational efficiency and sustainability. By choosing a trusted manufacturer with a proven track record, businesses can ensure continuous and reliable fluid management, reducing operational downtime and optimizing performance. With advancements in design and materials, centrifugal impeller pumps will continue to evolve, cementing their status as an essential component in modern industry operations.

From an authority standpoint, manufacturers are constantly innovating, drawing on deep research and insights into fluid dynamics. Partnerships with academic institutions and research bodies have resulted in cutting-edge designs that enhance pump performance and reduce energy consumption. These collaborations ensure centrifugal impeller pumps incorporate the latest technological advancements and best practices in sustainable engineering. When discussing centrifugal impeller pumps, trustworthiness is underscored by rigorous testing standards and certifications. Reputable manufacturers adhere to international quality standards such as ISO 9001 and ANSI/HI – standards that ensure each pump's reliability, safety, and performance are validated before reaching the market. These certifications are not just a mark of quality but a testament to the commitment of manufacturers to deliver tried-and-true products to their clients. Regarding installation and operation, users often seek professional guidance to optimize the setup and leverage the full potential of their centrifugal impeller pumps. Expert consultation is recommended to evaluate the specific requirements of the application, considering factors such as pump size, motor power, and impeller design. Experienced technicians can provide invaluable insights into selecting a pump that balances efficiency and effectiveness, considering the nuances of the particular industry and application. In summary, centrifugal impeller pumps are a robust and versatile solution for fluid transportation across numerous sectors. Their efficiency, coupled with low maintenance demands and adaptability, makes them an ideal choice for industries seeking to enhance operational efficiency and sustainability. By choosing a trusted manufacturer with a proven track record, businesses can ensure continuous and reliable fluid management, reducing operational downtime and optimizing performance. With advancements in design and materials, centrifugal impeller pumps will continue to evolve, cementing their status as an essential component in modern industry operations.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024