-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 18, 2025 05:19

Back to list

cement slurry pump

Cement slurry pumps are vital components in the construction and mining industries, playing a crucial role in transporting cement-based materials efficiently. These pumps are indispensable for projects that require the precise and consistent movement of slurries, particularly in large-scale construction environments. A deeper understanding of their applications, technology, and operational considerations can significantly enhance their effectiveness and lifespan.

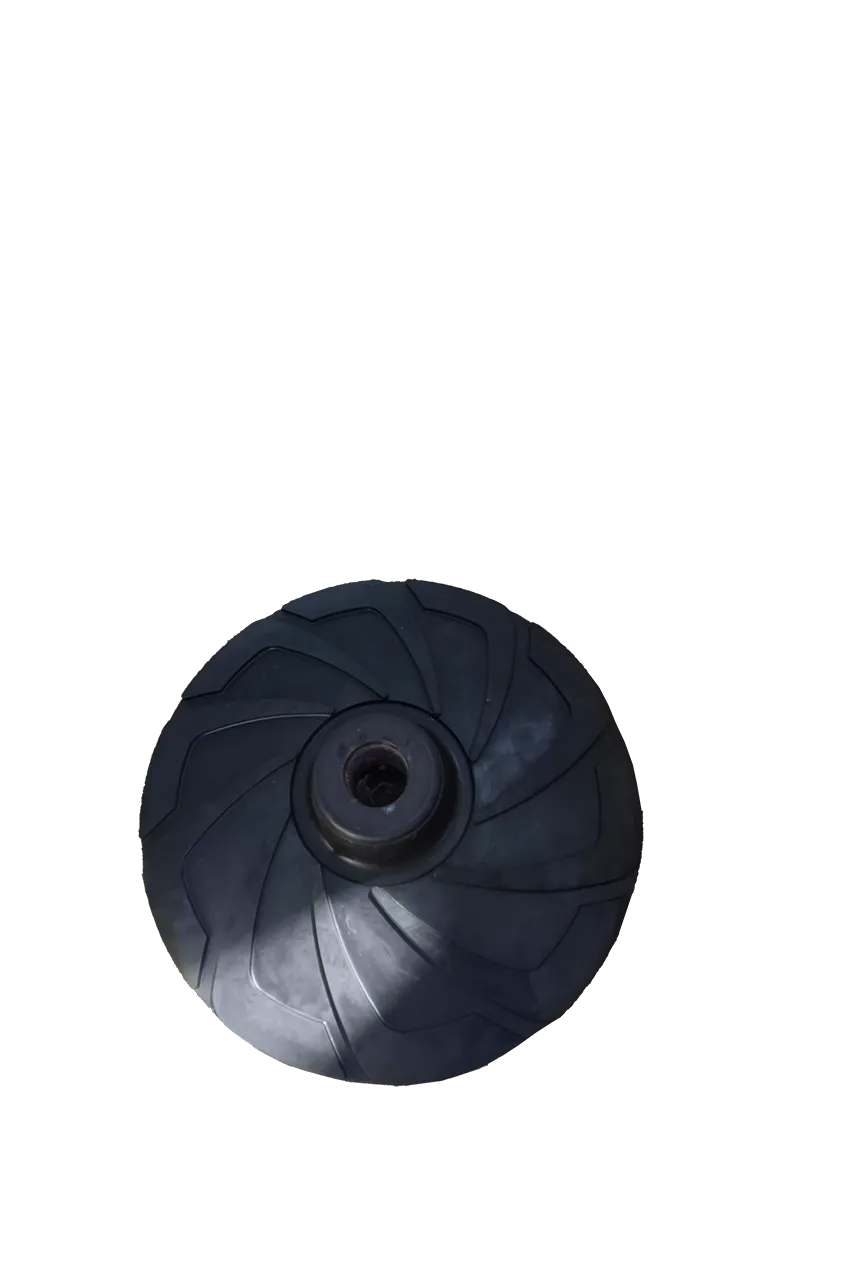

Real-world experience illustrates that successful implementation of a cement slurry pump in a project involves a strategic approach. Operators should conduct regular maintenance checks to preclude malfunctions. This involves routine inspections for wear on parts such as impellers and casing and proactive management to replace these components before they fail. Additionally, employing qualified technicians for pump operation and maintenance can further ensure the systems run smoothly, preserving both time and resources. The reliability of a cement slurry pump is often a reflection of its brand and the reputation it holds within the industry. Established manufacturers who have consistently delivered high-performing pumps are trusted across various sectors, not only due to their superior engineering but also their commitment to customer support and service. Strong after-sales services, including training and rapid response for spare parts, add a layer of trustworthiness that reassures clients their investment is in competent hands. When investing in a cement slurry pump, due diligence must also extend to understanding compliance and environmental considerations. Pump systems designed with the latest emission standards in mind or with capabilities to recycle and reduce waste during operations signify a commitment to sustainable practices. These considerations not only align with global sustainability goals but also position businesses as conscientious and forward-thinking leaders within their industries. In conclusion, the role of cement slurry pumps in construction and mining cannot be overstated. Their ability to efficiently transport abrasive materials with precision underpins successful project completions. Selecting the right pump encompasses a blend of technical prowess, expert guidance, and strategic maintenance. By prioritizing durability, efficiency, and compliance, companies can ensure their cement slurry pumps deliver optimal performance, reinforcing their operational goals and contributing to the broader success of their projects.

Real-world experience illustrates that successful implementation of a cement slurry pump in a project involves a strategic approach. Operators should conduct regular maintenance checks to preclude malfunctions. This involves routine inspections for wear on parts such as impellers and casing and proactive management to replace these components before they fail. Additionally, employing qualified technicians for pump operation and maintenance can further ensure the systems run smoothly, preserving both time and resources. The reliability of a cement slurry pump is often a reflection of its brand and the reputation it holds within the industry. Established manufacturers who have consistently delivered high-performing pumps are trusted across various sectors, not only due to their superior engineering but also their commitment to customer support and service. Strong after-sales services, including training and rapid response for spare parts, add a layer of trustworthiness that reassures clients their investment is in competent hands. When investing in a cement slurry pump, due diligence must also extend to understanding compliance and environmental considerations. Pump systems designed with the latest emission standards in mind or with capabilities to recycle and reduce waste during operations signify a commitment to sustainable practices. These considerations not only align with global sustainability goals but also position businesses as conscientious and forward-thinking leaders within their industries. In conclusion, the role of cement slurry pumps in construction and mining cannot be overstated. Their ability to efficiently transport abrasive materials with precision underpins successful project completions. Selecting the right pump encompasses a blend of technical prowess, expert guidance, and strategic maintenance. By prioritizing durability, efficiency, and compliance, companies can ensure their cement slurry pumps deliver optimal performance, reinforcing their operational goals and contributing to the broader success of their projects.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024