-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 06, 2025 05:39

Back to list

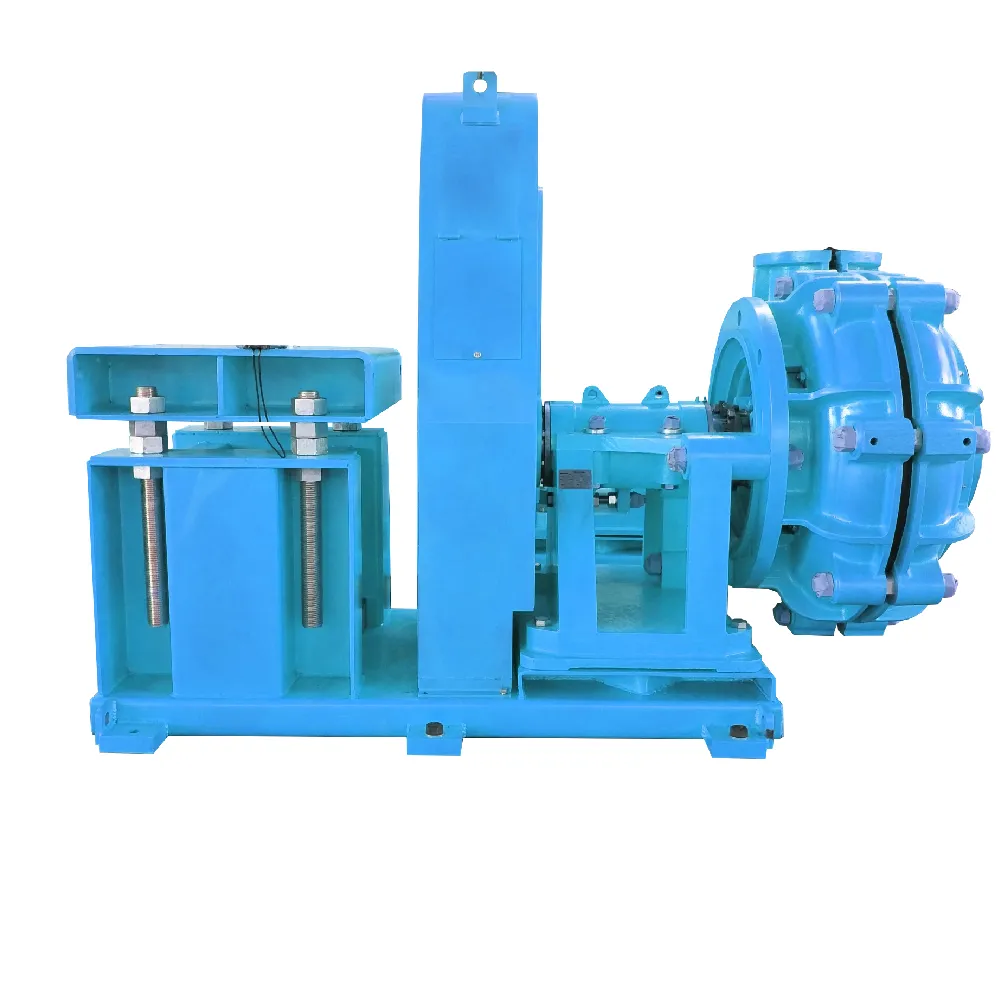

casting slurry pump part

The evolution of casting slurry pump parts has significantly advanced modern industrial processes, ensuring reliability and enhanced efficiency. As industries increasingly combat the challenges of abrasive and corrosive materials, these parts have become crucial in maintaining a seamless flow in operations, underlining their importance with an ever-growing demand.

Trustworthiness in casting slurry pump parts also stems from rigorous testing protocols. Each component undergoes thorough assessments to ensure compliance with the highest operational standards. Real-time feedback from field applications aids in refining these standards, providing continuous improvement in product offerings. Such diligence not only reassures clients of performance reliability but also fosters long-term strategic partnerships based on trust and shared success. Opting for cast slurry pump parts represents an investment in innovation and efficiency. It's an acknowledgment of the nuances distinguishing exemplary components capable of sustaining operations under the harshest conditions. By prioritizing the engineering precision and reliability associated with casting, industries are empowered to maximize productivity and minimize disruptions. In the competitive framework of industrial markets, where precision and dependability cannot be compromised, leveraging expert insights and cutting-edge technologies to source the best cast slurry pump parts becomes paramount. Consequently, businesses can dramatically elevate their operational output, reinforcing their commitment to excellence.

Trustworthiness in casting slurry pump parts also stems from rigorous testing protocols. Each component undergoes thorough assessments to ensure compliance with the highest operational standards. Real-time feedback from field applications aids in refining these standards, providing continuous improvement in product offerings. Such diligence not only reassures clients of performance reliability but also fosters long-term strategic partnerships based on trust and shared success. Opting for cast slurry pump parts represents an investment in innovation and efficiency. It's an acknowledgment of the nuances distinguishing exemplary components capable of sustaining operations under the harshest conditions. By prioritizing the engineering precision and reliability associated with casting, industries are empowered to maximize productivity and minimize disruptions. In the competitive framework of industrial markets, where precision and dependability cannot be compromised, leveraging expert insights and cutting-edge technologies to source the best cast slurry pump parts becomes paramount. Consequently, businesses can dramatically elevate their operational output, reinforcing their commitment to excellence.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024