-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 19, 2025 00:50

Back to list

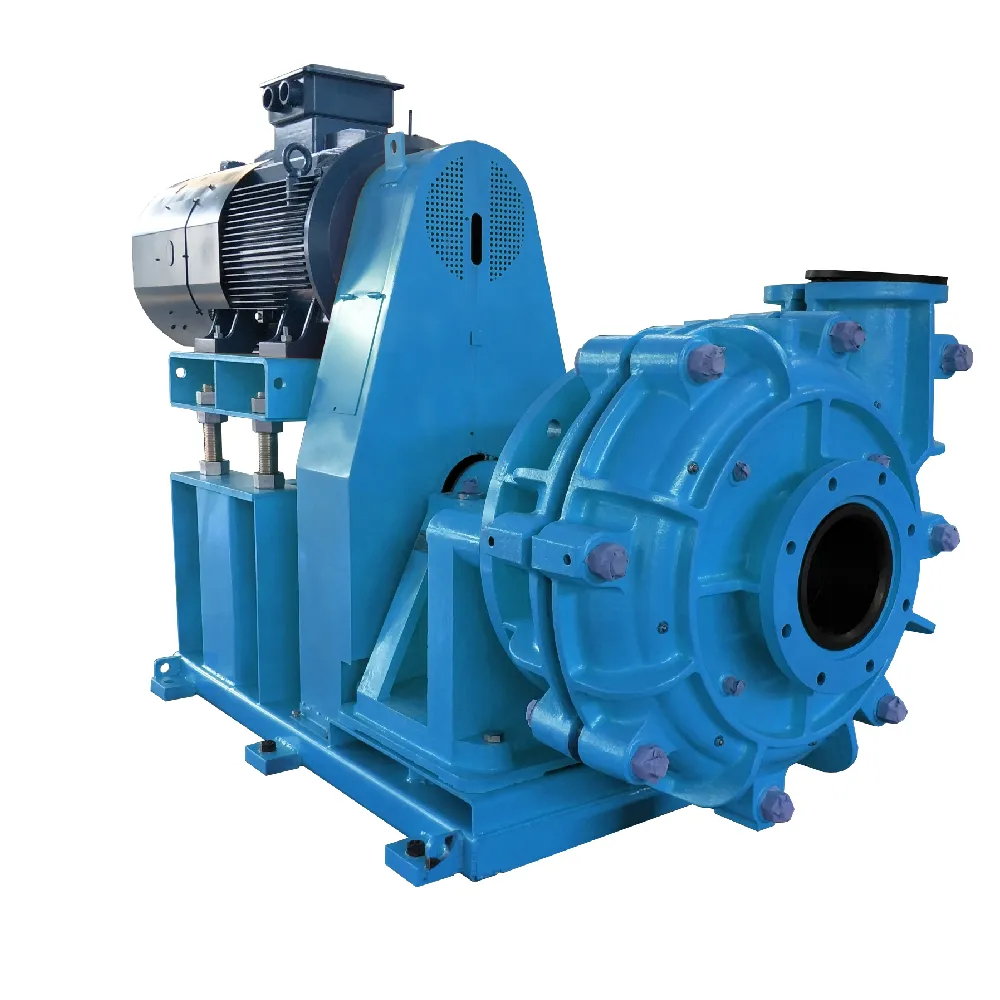

carbon slurry pump

In the dynamic realm of industrial machinery, the carbon slurry pump emerges as a pivotal tool utilized across various sectors, including mining, chemical processing, and wastewater treatment. This advanced piece of equipment plays a crucial role in the efficient handling and transport of abrasive fluids. With their robust design and superior material composition, carbon slurry pumps are built to withstand harsh operational environments, ensuring longevity and consistent performance.

Trustworthiness is a crucial attribute for any product operating in industrial settings, and carbon slurry pumps have earned such trust due to their robust performance over the years. Industry professionals vouch for these pumps, as numerous case studies highlight their ability to drastically reduce maintenance costs while maximizing uptime. Furthermore, companies that employ carbon slurry pumps have reported improved employee safety, as these pumps handle hazardous slurries with minimal human intervention. Beyond their functional prowess, carbon slurry pumps also contribute to environmental sustainability. By ensuring efficient slurry transport, these pumps help in the reduction of energy consumption and carbon emissions. Innovations in pump design, such as energy-efficient motors and optimized flow paths, underscore the commitment to reducing the ecological footprint of industrial processes. For businesses considering investing in carbon slurry pumps, the myriad benefits—ranging from operational efficiency and cost savings to sustainability and safety—are compelling. Selecting the appropriate pump model requires a detailed analysis of specific operational needs, including slurry composition, flow rate, and operating pressure. Collaboration with reputable manufacturers is essential in this selection process to ensure the pump meets the intended application requirements. In conclusion, the carbon slurry pump represents a blend of experience-backed reliability, expert craftsmanship, authoritative performance, and unrivaled trustworthiness. As industries continue to evolve, these pumps will remain critical in enhancing operational efficiencies and meeting environmental standards, thereby solidifying their indispensable role in modern industrial operations.

Trustworthiness is a crucial attribute for any product operating in industrial settings, and carbon slurry pumps have earned such trust due to their robust performance over the years. Industry professionals vouch for these pumps, as numerous case studies highlight their ability to drastically reduce maintenance costs while maximizing uptime. Furthermore, companies that employ carbon slurry pumps have reported improved employee safety, as these pumps handle hazardous slurries with minimal human intervention. Beyond their functional prowess, carbon slurry pumps also contribute to environmental sustainability. By ensuring efficient slurry transport, these pumps help in the reduction of energy consumption and carbon emissions. Innovations in pump design, such as energy-efficient motors and optimized flow paths, underscore the commitment to reducing the ecological footprint of industrial processes. For businesses considering investing in carbon slurry pumps, the myriad benefits—ranging from operational efficiency and cost savings to sustainability and safety—are compelling. Selecting the appropriate pump model requires a detailed analysis of specific operational needs, including slurry composition, flow rate, and operating pressure. Collaboration with reputable manufacturers is essential in this selection process to ensure the pump meets the intended application requirements. In conclusion, the carbon slurry pump represents a blend of experience-backed reliability, expert craftsmanship, authoritative performance, and unrivaled trustworthiness. As industries continue to evolve, these pumps will remain critical in enhancing operational efficiencies and meeting environmental standards, thereby solidifying their indispensable role in modern industrial operations.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024