-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 15, 2025 08:56

Back to list

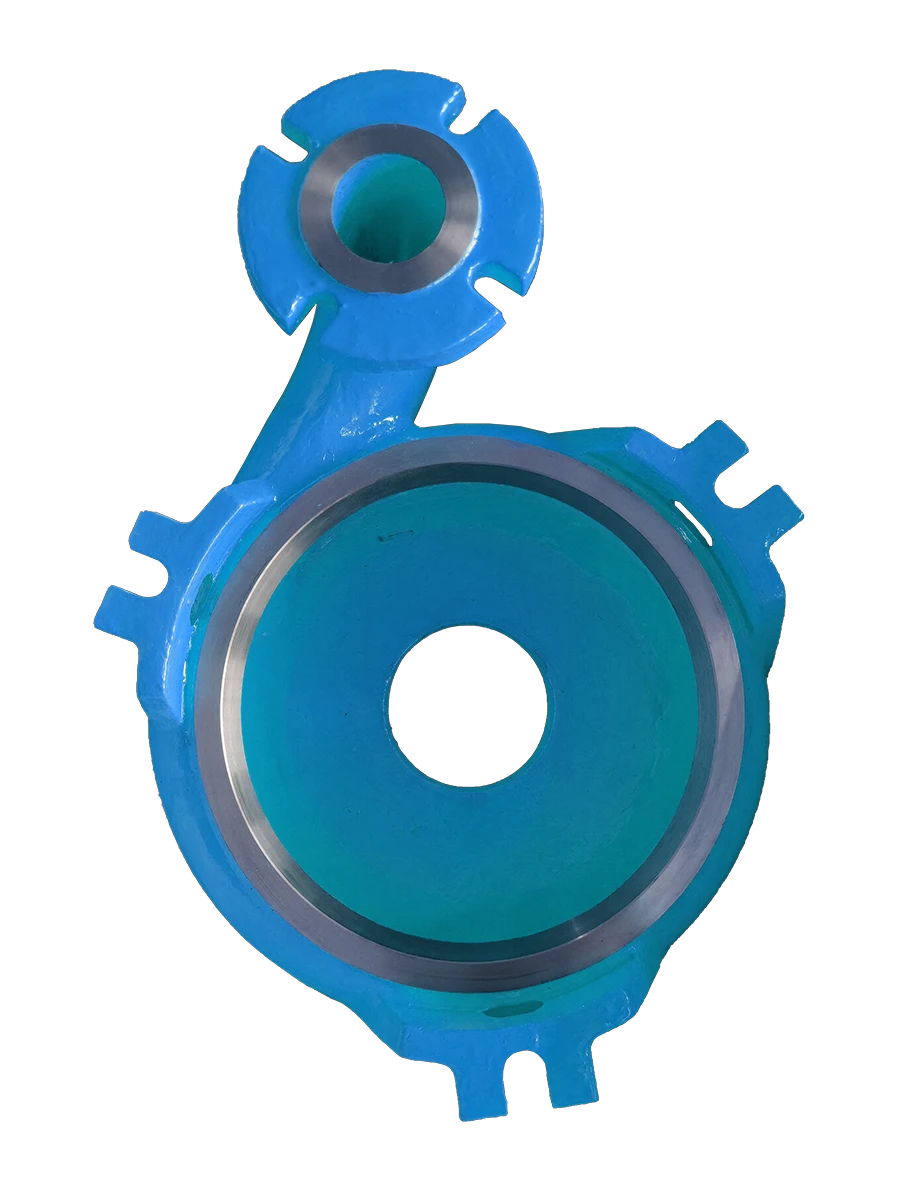

axially split volute casing pump

Axially split volute casing pumps, a cornerstone in modern fluid transportation systems, stand as a testament to engineering excellence and innovation. These pumps, known for their unique construction and superior efficiency, have become an indispensable asset across multiple industries, demonstrating unmatched reliability and performance. The following sections delve into the myriad advantages, applications, and technical nuances of axially split volute casing pumps, offering a comprehensive view backed by decades of industry expertise.

In terms of authority and trustworthiness, axially split volute casing pumps comply with stringent industry standards and certifications. Trusted manufacturers subject these pumps to rigorous testing and quality assurance processes to guarantee consistent performance. By adhering to protocols set forth by organizations such as the American National Standards Institute (ANSI) and the Hydraulic Institute, these pumps assure stakeholders of their commitment to quality and safety. The real-world experiences shared by industry leaders further solidify the authority of these pumps. Testimonials from facilities utilizing these pumps often highlight the tangible benefits observed—reduced maintenance costs, increased operational uptime, and enhanced process efficiency. Such endorsements reflect not only the technical advantages but also the economic and practical benefits these pumps provide. For decision-makers evaluating potential fluid management solutions, the axially split volute casing pump represents a harmonious blend of cutting-edge design, professional reliability, and proven performance metrics. Its utility is not merely theoretical but grounded in extensive field application across diverse sectors. By choosing this pump, businesses align themselves with a product backed by extensive research and a proven track record of excellence. In conclusion, the axially split volute casing pump represents more than a mechanical device; it embodies a tradition of technical excellence and reliability. Its sophisticated design, coupled with practical advantages, makes it an irreplaceable component in contemporary engineering projects. By investing in this technology, industries not only enhance their operational capabilities but also contribute to a legacy of innovation and efficiency in fluid transport solutions.

In terms of authority and trustworthiness, axially split volute casing pumps comply with stringent industry standards and certifications. Trusted manufacturers subject these pumps to rigorous testing and quality assurance processes to guarantee consistent performance. By adhering to protocols set forth by organizations such as the American National Standards Institute (ANSI) and the Hydraulic Institute, these pumps assure stakeholders of their commitment to quality and safety. The real-world experiences shared by industry leaders further solidify the authority of these pumps. Testimonials from facilities utilizing these pumps often highlight the tangible benefits observed—reduced maintenance costs, increased operational uptime, and enhanced process efficiency. Such endorsements reflect not only the technical advantages but also the economic and practical benefits these pumps provide. For decision-makers evaluating potential fluid management solutions, the axially split volute casing pump represents a harmonious blend of cutting-edge design, professional reliability, and proven performance metrics. Its utility is not merely theoretical but grounded in extensive field application across diverse sectors. By choosing this pump, businesses align themselves with a product backed by extensive research and a proven track record of excellence. In conclusion, the axially split volute casing pump represents more than a mechanical device; it embodies a tradition of technical excellence and reliability. Its sophisticated design, coupled with practical advantages, makes it an irreplaceable component in contemporary engineering projects. By investing in this technology, industries not only enhance their operational capabilities but also contribute to a legacy of innovation and efficiency in fluid transport solutions.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024