-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 29, 2025 04:45

Back to list

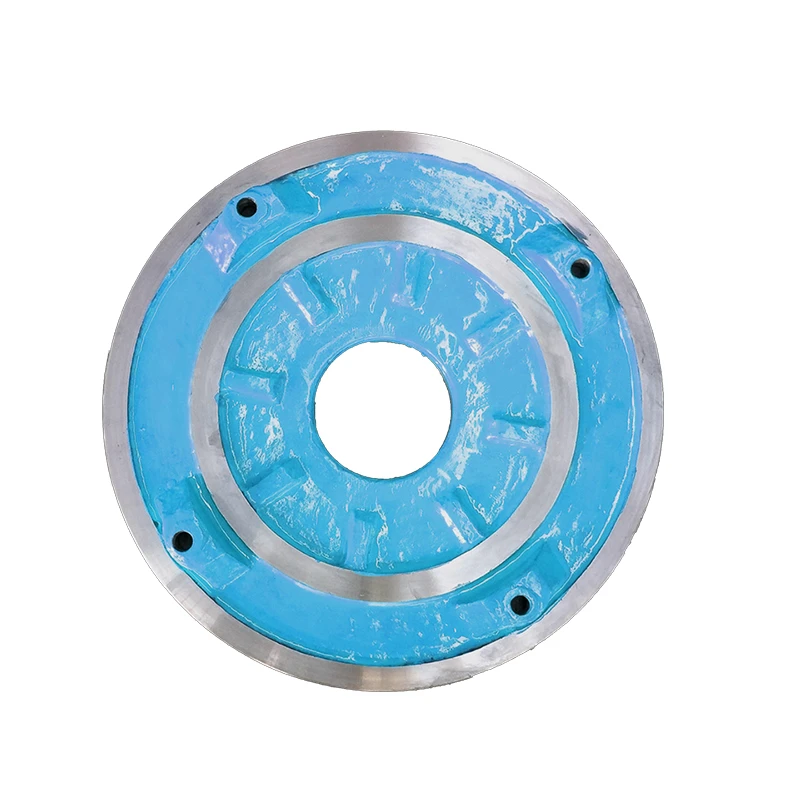

ah slurry pump parts

Selecting the right slurry pump parts is a crucial decision in the maintenance and sustainability of industrial and mining operations. To optimize the longevity and efficiency of slurry pumps, it's essential to grasp the intricacies of various components, their material composition, and application suitability.

Efficient maintenance schedules integrate routine inspection procedures and predictive maintenance technologies to preemptively detect wear or fault lines in slurry pump parts. Employing technologies like vibration analysis and acoustic monitoring can effectively detect anomalies, suggesting early intervention points for replacing, upgrading, or refurbishing specific components before failure occurs. Working with recognized and experienced manufacturers elevates the quality assurance and warranty potential of the slurry pump parts. An experienced manufacturer often offers the advantage of precision engineering and post-purchase support, which includes training in installation and maintenance services. There is a substantial value in partnering with suppliers that provide comprehensive lifecycle support, including parts inventory management and expedited delivery services to minimize downtime during maintenance windows. Continuously updated performance records and real-time data analyses from your operations serve as a foundational practice for evidence-based decision-making. Ensuring that these records are maintained with high fidelity helps in assessing any historical wear patterns or failure modes that might be specific to your operational context. Ultimately, optimizing slurry pump part selection emphasizes not just immediate operational efficiency, but also the total cost of ownership over the lifespan of the pump system. By considering factors such as material compatibility, component design, and preventive maintenance, operators can vastly improve efficiency, reliability, and the operational lifespan of slurry pumping systems. This strategic approach marries field insights with technical expertise, validating an organization's authority and expertise in managing high-stakes industrial environments.

Efficient maintenance schedules integrate routine inspection procedures and predictive maintenance technologies to preemptively detect wear or fault lines in slurry pump parts. Employing technologies like vibration analysis and acoustic monitoring can effectively detect anomalies, suggesting early intervention points for replacing, upgrading, or refurbishing specific components before failure occurs. Working with recognized and experienced manufacturers elevates the quality assurance and warranty potential of the slurry pump parts. An experienced manufacturer often offers the advantage of precision engineering and post-purchase support, which includes training in installation and maintenance services. There is a substantial value in partnering with suppliers that provide comprehensive lifecycle support, including parts inventory management and expedited delivery services to minimize downtime during maintenance windows. Continuously updated performance records and real-time data analyses from your operations serve as a foundational practice for evidence-based decision-making. Ensuring that these records are maintained with high fidelity helps in assessing any historical wear patterns or failure modes that might be specific to your operational context. Ultimately, optimizing slurry pump part selection emphasizes not just immediate operational efficiency, but also the total cost of ownership over the lifespan of the pump system. By considering factors such as material compatibility, component design, and preventive maintenance, operators can vastly improve efficiency, reliability, and the operational lifespan of slurry pumping systems. This strategic approach marries field insights with technical expertise, validating an organization's authority and expertise in managing high-stakes industrial environments.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024