-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 18, 2025 08:39

Back to list

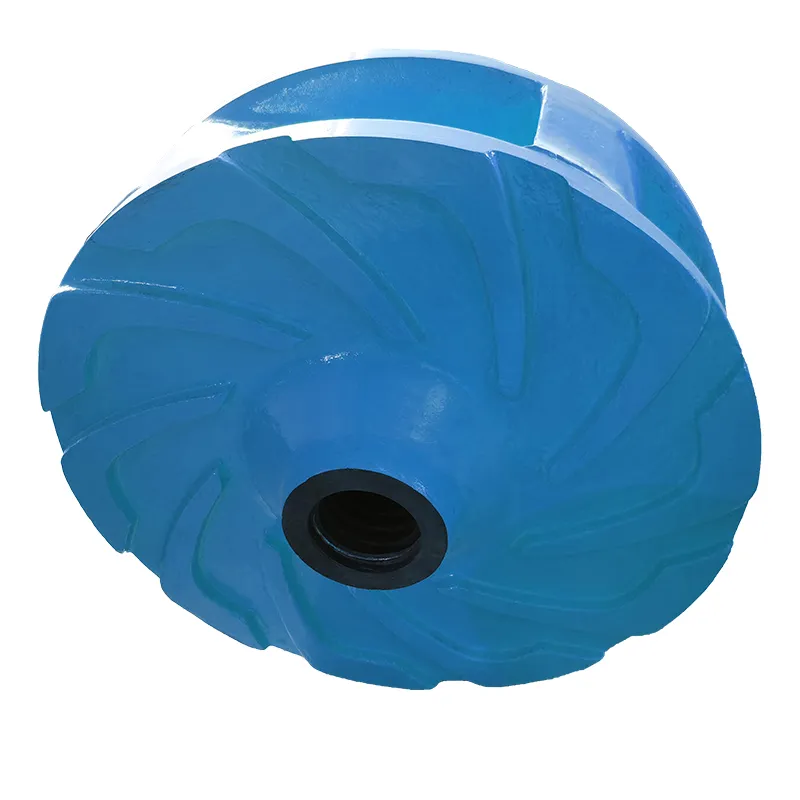

abrasive slurry pump

For industries involved in the handling of heavy solids and viscous substances, the selection of the correct abrasive slurry pump is paramount. These pumps are engineered to transfer fluids containing abrasive particles efficiently, making them essential in sectors like mining, construction, and wastewater management. Choosing an abrasive slurry pump requires a comprehensive understanding of the application parameters, technical specifications, and operational requirements to ensure optimal performance and longevity.

Building trust through the selection of an abrasive slurry pump involves transparency and adherence to industry standards. Certification and compliance with international standards, such as ISO and ANSI, affirm the pump's quality and safety credentials. Moreover, manufacturers offering extensive warranties on their products can often be perceived as more trustworthy, as these guarantees reflect their confidence in the pump's durability and performance. Trust is further established through user reviews and peer recommendations, where real-world experiences offer invaluable insights into the pump's operational reliability. When evaluating the operational aspects of an abrasive slurry pump, one must not overlook the pump's efficiency and energy consumption. Advanced designs focusing on hydraulic efficiency not only improve the pump's performance but also contribute to energy savings, which is a significant consideration given rising energy costs. Experts in the field advocate for the adoption of pumps with adjustable speed controls and smart monitoring systems, as these features allow for optimization of the pump's operation according to the varying demands of the application. In conclusion, the successful implementation and operation of an abrasive slurry pump are contingent upon a balanced consideration of experience, expertise, authoritativeness, and trustworthiness. By leveraging these four pillars, industries can achieve greater operational efficiency, reduced maintenance costs, and enhanced productivity. Those seeking to invest in abrasive slurry pumps should prioritize comprehensive research, collaboration with reputable manufacturers, and alignment with industry best practices to ensure that the chosen solution perfectly meets their application needs.

Building trust through the selection of an abrasive slurry pump involves transparency and adherence to industry standards. Certification and compliance with international standards, such as ISO and ANSI, affirm the pump's quality and safety credentials. Moreover, manufacturers offering extensive warranties on their products can often be perceived as more trustworthy, as these guarantees reflect their confidence in the pump's durability and performance. Trust is further established through user reviews and peer recommendations, where real-world experiences offer invaluable insights into the pump's operational reliability. When evaluating the operational aspects of an abrasive slurry pump, one must not overlook the pump's efficiency and energy consumption. Advanced designs focusing on hydraulic efficiency not only improve the pump's performance but also contribute to energy savings, which is a significant consideration given rising energy costs. Experts in the field advocate for the adoption of pumps with adjustable speed controls and smart monitoring systems, as these features allow for optimization of the pump's operation according to the varying demands of the application. In conclusion, the successful implementation and operation of an abrasive slurry pump are contingent upon a balanced consideration of experience, expertise, authoritativeness, and trustworthiness. By leveraging these four pillars, industries can achieve greater operational efficiency, reduced maintenance costs, and enhanced productivity. Those seeking to invest in abrasive slurry pumps should prioritize comprehensive research, collaboration with reputable manufacturers, and alignment with industry best practices to ensure that the chosen solution perfectly meets their application needs.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024