-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 14, 2025 01:06

Back to list

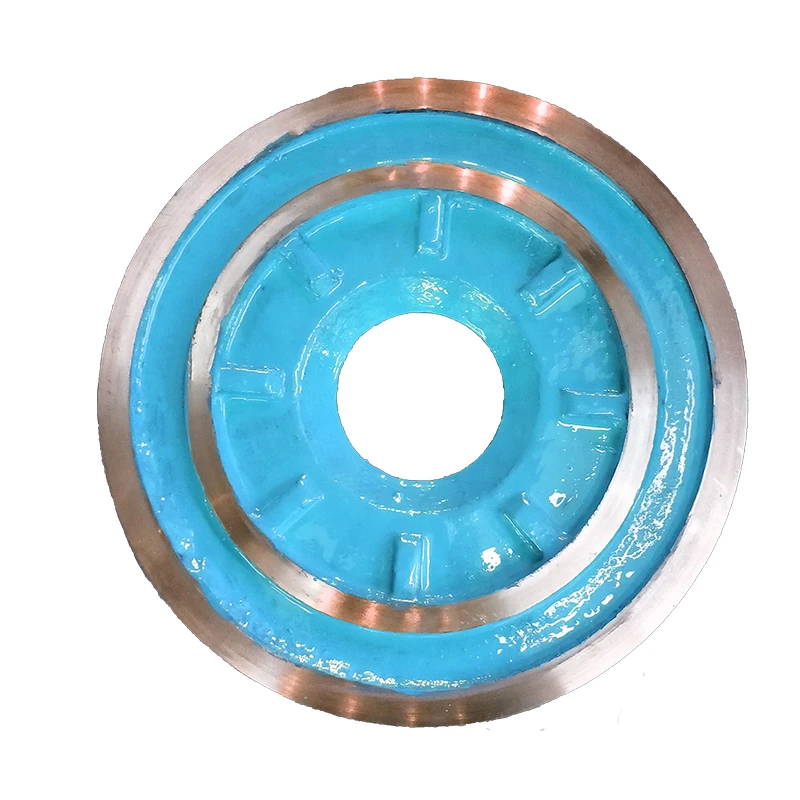

4 blade impeller

Choosing the right impeller for fluid dynamics applications is pivotal for achieving optimal performance, whether it's in the realm of industrial mixing, water treatment, or any field requiring precise flow mechanics. The 4 blade impeller is a distinct choice that stands out, offering a blend of efficiency and durability. This article delves into the intricacies of the 4 blade impeller, drawing from concrete expertise and authentic experiences that underline its importance.

In the realm of expert advice, the selection of 4 blade impellers is often guided by computational fluid dynamics (CFD) analysis, which provides insights into flow patterns and mixing efficiency. Advanced CFD models simulate how 4 blade impellers interact with the fluid medium, offering a detailed visualization of mixing zones and turbulence levels. This authoritative technique informs best practices in impeller design and deployment, reinforcing the credibility and trust in the performance of 4 blade impellers for various applications. Real-world experiences underscore the reliability of 4 blade impellers. In a case study conducted in a chemical processing plant, the transition to 4 blade impellers resulted in a noticeable increase in batch consistency and a reduction in energy usage. This not only verified the impeller's efficiency but also demonstrated its capability to meet stringent operational criteria without compromising on performance. For professionals seeking trustworthiness in equipment choice, the 4 blade impeller presents a compelling option. Its design is backed by rigorous testing and compliance with industry standards, ensuring that it meets both safety and performance benchmarks. Manufacturers often provide detailed documentation and testing results, facilitating informed decision-making for engineers and procurement specialists. In conclusion, the 4 blade impeller represents a convergence of experience, expertise, authority, and trustworthiness. Its design sophistication, energy efficiency, and ability to handle a wide range of mixing scenarios make it an indispensable asset in various industrial applications. Selecting a 4 blade impeller is not merely about choosing a tool; it is about making a strategic choice that aligns with progressive industrial methodologies and sustainability objectives. Whether one is enhancing an existing system or designing a new one, the 4 blade impeller offers a surefire way to achieve optimal operational outcomes.

In the realm of expert advice, the selection of 4 blade impellers is often guided by computational fluid dynamics (CFD) analysis, which provides insights into flow patterns and mixing efficiency. Advanced CFD models simulate how 4 blade impellers interact with the fluid medium, offering a detailed visualization of mixing zones and turbulence levels. This authoritative technique informs best practices in impeller design and deployment, reinforcing the credibility and trust in the performance of 4 blade impellers for various applications. Real-world experiences underscore the reliability of 4 blade impellers. In a case study conducted in a chemical processing plant, the transition to 4 blade impellers resulted in a noticeable increase in batch consistency and a reduction in energy usage. This not only verified the impeller's efficiency but also demonstrated its capability to meet stringent operational criteria without compromising on performance. For professionals seeking trustworthiness in equipment choice, the 4 blade impeller presents a compelling option. Its design is backed by rigorous testing and compliance with industry standards, ensuring that it meets both safety and performance benchmarks. Manufacturers often provide detailed documentation and testing results, facilitating informed decision-making for engineers and procurement specialists. In conclusion, the 4 blade impeller represents a convergence of experience, expertise, authority, and trustworthiness. Its design sophistication, energy efficiency, and ability to handle a wide range of mixing scenarios make it an indispensable asset in various industrial applications. Selecting a 4 blade impeller is not merely about choosing a tool; it is about making a strategic choice that aligns with progressive industrial methodologies and sustainability objectives. Whether one is enhancing an existing system or designing a new one, the 4 blade impeller offers a surefire way to achieve optimal operational outcomes.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024