-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

3 月 . 07, 2025 01:54

Back to list

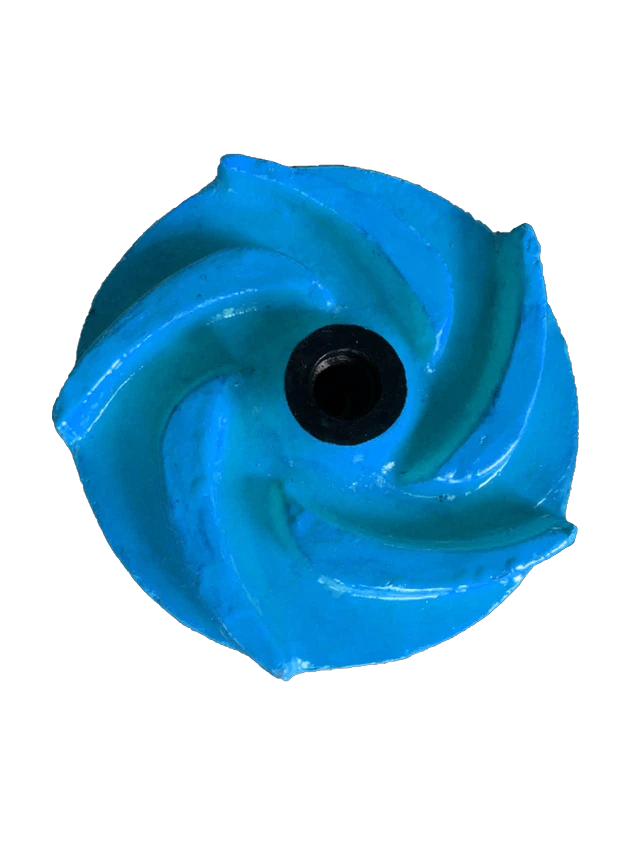

12 inch slurry pump

Unlock the potential of industrial operations with the unparalleled capabilities of a 12 inch slurry pump. Designed to meet the rigorous demands of modern engineering, these pumps stand as giants in the sphere of material handling, crucial for sectors such as mining, construction, and chemical processing.

In assessing the trustworthiness of utilizing a 12 inch slurry pump, one must acknowledge the advancements in sealing technology, which play a pivotal role in preserving both the pump and the environment. Modern pumps are equipped with sophisticated sealing systems such as gland packing seals and mechanical seals that prevent slurry leakage. This aspect is paramount, ensuring compliance with stringent environmental regulations and safeguarding the surrounding ecosystem. The usage scenarios for a 12 inch slurry pump are diverse. In mining, for instance, these pumps efficiently transport tailings from the processing plant, which is an arduous task due to the density and abrasiveness of the materials involved. Similarly, in the construction sector, these pumps find their niche in dewatering canals and trenches filled with sediment-laden water, showcasing their versatility and indispensability. In choosing the right 12 inch slurry pump, consideration of specific application needs is fundamental. Factors such as the type of slurry, required flow rate, and pipeline layout dictate the optimal pump configuration. Consultations with experts and industry specialists can guide informed decisions and ensure that the right equipment is selected for the task. Finally, integrating a monitoring system with a 12 inch slurry pump can significantly enhance its operational efficiency and reliability. Advanced monitoring tools provide real-time data analytics, allowing for predictive maintenance and averting potential failures before they occur. This integration, coupled with expertise in data interpretation, aids in maximizing pump productivity and longevity. In summary, the 12 inch slurry pump is a testament to innovation and engineering expertise, designed to address the modern challenges of material transport in industrial operations. For professionals looking to leverage this technology, understanding the intricate details of its design, capabilities, and operational efficiencies can open doors to enhanced productivity and sustainability in their projects.

In assessing the trustworthiness of utilizing a 12 inch slurry pump, one must acknowledge the advancements in sealing technology, which play a pivotal role in preserving both the pump and the environment. Modern pumps are equipped with sophisticated sealing systems such as gland packing seals and mechanical seals that prevent slurry leakage. This aspect is paramount, ensuring compliance with stringent environmental regulations and safeguarding the surrounding ecosystem. The usage scenarios for a 12 inch slurry pump are diverse. In mining, for instance, these pumps efficiently transport tailings from the processing plant, which is an arduous task due to the density and abrasiveness of the materials involved. Similarly, in the construction sector, these pumps find their niche in dewatering canals and trenches filled with sediment-laden water, showcasing their versatility and indispensability. In choosing the right 12 inch slurry pump, consideration of specific application needs is fundamental. Factors such as the type of slurry, required flow rate, and pipeline layout dictate the optimal pump configuration. Consultations with experts and industry specialists can guide informed decisions and ensure that the right equipment is selected for the task. Finally, integrating a monitoring system with a 12 inch slurry pump can significantly enhance its operational efficiency and reliability. Advanced monitoring tools provide real-time data analytics, allowing for predictive maintenance and averting potential failures before they occur. This integration, coupled with expertise in data interpretation, aids in maximizing pump productivity and longevity. In summary, the 12 inch slurry pump is a testament to innovation and engineering expertise, designed to address the modern challenges of material transport in industrial operations. For professionals looking to leverage this technology, understanding the intricate details of its design, capabilities, and operational efficiencies can open doors to enhanced productivity and sustainability in their projects.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024